Why are breathers necessary?

In fact it’s simple why breathers are necessary.

When buying industrial equipment, OEM include vent caps on the fill port.

Maybe you wonder, and ask yourself: “Isn’t that enough?”

Consider: your industrial machine heats up and cools down, consequently expands and contracts.

OEM added a vent cap to keep machines from building up too much pressure, allowing expanded air to escape.

However……. those caps don’t prevent small particles from entering the equipment.

And there the trouble starts!

Dirty particles, even smaller than 1/10 the size of a human hair, damage gears, bearings and valves; they wear away the critical surfaces and will, over time, condense inside your oil reservoir.

And then the harm has been done…… water is introduced to your lubricants!

That’s why desiccant breathers are absolutely necessary.

They reduce particulate and moisture contamination in fluids and equipment.

How do Breathers work

To give you an idea about how desiccant breathers are working, please find below a short explanation.

Air Sentry breathers replace existing breather caps or air vents on fluid holding storage tanks, hydraulic reservoirs and gear boxes. More older style venting air methods provide minimal if any contamination control.

Air Sentry breathers provide the FIRST LINE OF DEFENSE in contamination control methodology, utilizing patented designs and featuring colour indicating silica gel and self-cleaning 2-micron filtration.

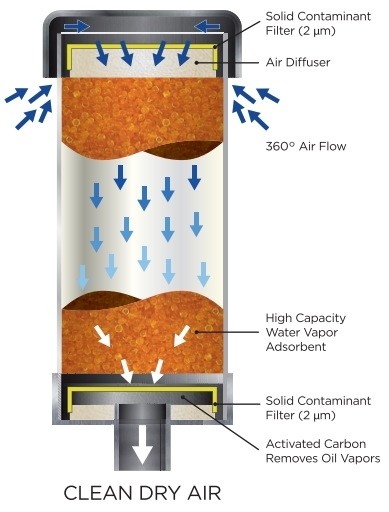

Diagram 1

DIAGRAM 1 indicates how the Air Sentry patented design allows outside air to enter through the 360° opening in the breather’s top cap.

The top cap design overhangs the body of the breather protecting it from rain, sleet, snow, as well as most equipment wash-down procedures.

When contaminated air enters the top of the breather, it passes through a self-cleaning solid particle filter. This filter traps solid particles greater than 2 micron and keeps them from entering the breather which ultimately which wear on your equipment. The filtered air then passes through a bed of silica gel that adsorbs moisture in the air. During this step, up to 95% of the water vapor in the air is filtered out.

Finally, the filtered air passes through an additional 2 micron filter in the bottom of the breather to ensure that no harmful particles will enter the tank or reservoir. This three stage filtration design ensures your equipment gets CLEAN, DRY AIR!

As the colour indicating silica gel adsorbs moisture it changes from gold to dark green. When the silica gel is adsorbed to its capacity (approximately 40% of its original weight), the breather has fully turned dark green. This colour change is easily seen and serves as the visual indication that it is time to remove and replace the disposable breather.

Diagram 2

DIAGRAM 2 indicates air being expelled back through the desiccant breather from the equipment it is mounted on. As contaminated air travels this reverse path, expelled water vapors are adsorbed by the silica gel. During this reverse air flow process, the silica gel indicates the presence of excessive moisture inside the reservoir as the gold silica gel turns to dark green from the bottom of the breather rather than from the top of the breather.

An additional feature located in the bottom of most Air Sentry® models is a layer of carbon impregnated foam. This carbon pad absorbs small amounts of oil vapor exhaled from the tank and protects the silica gel from minor oil mist contamination. Excessive oil mist control may be required.

Adapters are available for applications with excessive oil mist problems. As the exhausted air passes back through the self cleaning 2-micron filter, located in the top cap of the breather, any particles that were trapped as air entered the system are now back flushed from the filter.

With a wide range of features and sizes, in almost any application, Air Sentry desiccant breathers remove moisture with silica gel and by using multi-layer filtration. Thereby preventing that the smallest particles enter your oil tanks.

Good Solutions

D-SERIES

D-Series breathers feature numerous models in a variety of sizes. They are fully disposable and designed to satisfy the requirements of most stationary fluid management applications.

Stationary applications:

- Oil Storage Tanks

- Fluid Reservoirs

- Transformers

- Pumps

- Gearboxes

- Small Oil Containers

Z-SERIES

Z-Series desiccant breathers (Mini Breather line) are designed for applications with space limitations or minimal airflow requirements. Five standard models. Diameter: 2” and 3.25” Length: 2” to 5.5” Mounting..

Limited space applications:

- Gearboxes

- Drums

- Totes

- Small Oil Containers

Better Solutions

X-SERIES

X-Series breathers are a better solution for high humidity and high dust environments.

High humidity/-dust applications

- Paper Mill

- Wash-down areas

- Steam-Cleaning Rooms

- Mine Quarries

Best Solutions

Guardian-Series

Guardian is Air Sentry’s industry leading breather series. Some models feature check valve that keeps exhaust air from depleting the desiccant and protects from volatile foams and splashing fluids.

Ideal for most applications

The Guardian is the only desiccant breather series that Air Sentry recommends for diesel fuel applications. (Not recommended for other fuel applications)

Other Series Solutions

L-Series:

Air Sentry® In-Line Filter / Dryers remove water vapor and solid contaminants from air exhaust lines, low pressure compressed air lines, vacuum lines, and other in-line airflow applications where clean, dry air is required.

- The L-Series is rated up to 60 psi and mounted on the regulated side of the air line.

- The L-Series breathers are available with 100% silica gel or activated carbon, or a combination of both, as necessary.

- Air enters the filter / dryer in one end and is clean and dry when leaving the other end.

- Water vapor and solid particles down to 2 micron are removed.

In-Line low airflow applications:

- Air Exhaust Lines

- Vacuum Lines

- Low pressure compressed air lines

- Marine vehicles

M-Series:

M-Series breathers are designed from heavy-duty materials capable of handling the requirements of the most severe environments. They replace the standard breather cap or vent tube on fuel tanks and fluid reservoirs. Pipe threads on the bottom standpipe make the units easy to install in moments.All M-Series designs have 2 micron pleated filters and silica gel bags that are easily replaced. They also feature the proprietary Splash Sentry™, which prevents foaming or splashing fluids from entering the breather during normal operating conditions.

Heavy Duty Applications:

- Heavy Duty Off-Road Equipment

- Heavy Mobile Equipment

- High Temperatures

- Corrosive Chemicals

R-Series:

R-Series Breathers are ideal for heavy equipment that is productive and on the move and outfitted with hydraulic fluid tanks or reservoirs that breathe in the dirty outside air. This heavy-duty breather series is designed for high-vibration, mobile applications, to include, off-road, construction and farm vehicles. R-Series breathers easily mount in place of standard breather caps by rugged steel pipe threads and a reusable metal base.

Heavy Equipment Applications:&