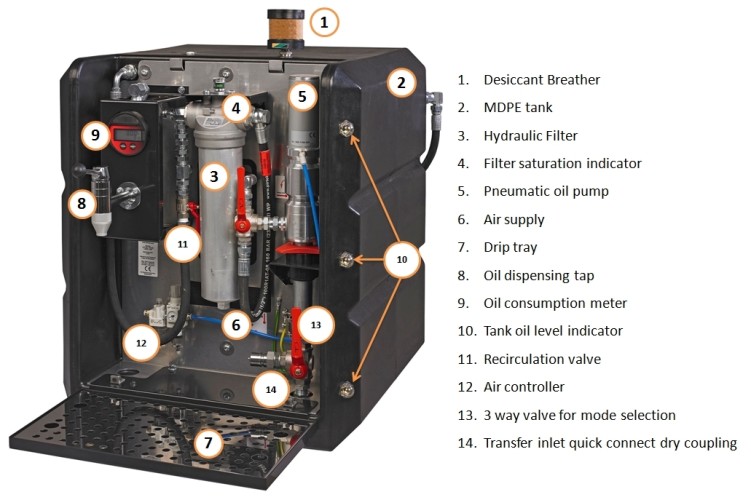

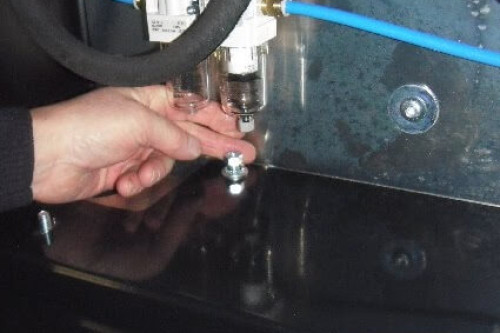

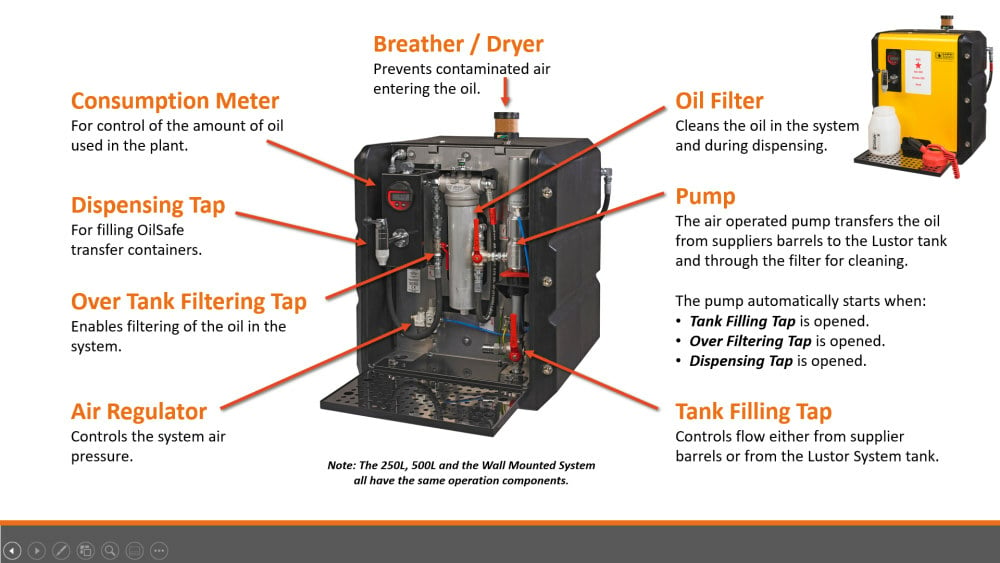

1. 10-micron large filter

To achieve and maintain the appropriate cleanliness level in the system, a 10 mµ Hydraulic filter with saturation indicator is installed.

Change/upgrades available to:

- 3 mµ small filter cartridge

- 3 mµ small filter / stat free cartridge

- 3 mµ large filter / high viscosity oils / stat free cartridge

- 10 mµ small filter cartridge

- 10 mµ small filter / stat free cartridge

- 10 mµ small filter / stat free / high viscosity oils cartridge

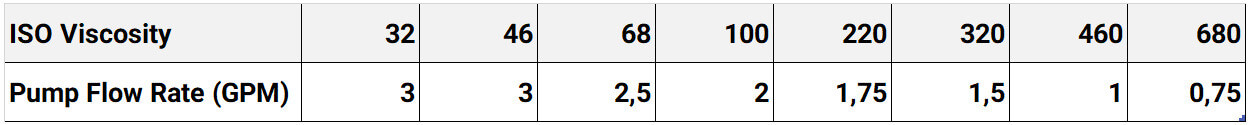

2. Pneumatic 3:1 air pump

If the air-input pressure is 100 psi, a pump ratio of 3:1 will yield a fluid-output pressure of 300 psi. Upgrade to 5:1 ratio pump available (used with hose reel)

3. Dispensing tap

High quality auto-shut off tap. Self closing faucets assure no mess or waste when dispensing fluids from the Lustor System.

4. Oil consumption meter

A nice feature to track the oil consumption

5. 3-D BullsEyes*

The perfect solution for quick oil level inspection in the tank. The 3-D BullsEye* gives a 360° view of oil clarity and colour, and monitors the oil level.

*The 3-D BullsEye is a clear cylinder made from one solid piece of acrylic with threading on one end and a rounded polished end for easier viewing of the oil on the other end.

6. Gauge

Filter heads have differential visual indicators for filter element indicators. They will turn red when filter element requires service.

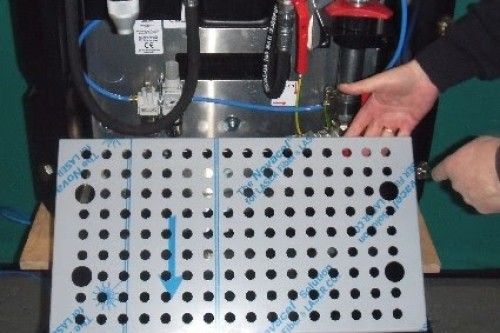

7. Air Controller

It is recommended that the main air supply line to the system or lube room has a main shut off valve and that each system has its own individual shut off valve.

The air controller is preset during assembly. This is set to 2 bar, Do not run the System above 2 bar. Running above 2 bar can result in oil cavitation!

It is recommended that the main air supply line to the system or lube room has a main shut off valve and that each system has its own individual shut off valve. The air supply line is recommended to be not less than 6 mm diameter.

Note:

When the System is used for the first time there may be some air that has been trapped in the piping System. This is normal and will not affect the System operation. Simply wait for the excess air to be depleted and fluids start to dispense normally.

The air supply line is recommended to be not less than 6 mm diameter.