Have you ever wondered why machines fail?

There are many reasons why machines fail. Too many to mention them all. But one of the critical causes is the need to control the ingress of contamination, which too often enters our machinery. As well as ensuring that the correct quality and grade goes into the machines.

Have you ever left your lubricants open to dirt and moisture next to your machine? Then no doubt you still use the old oil can with rags; the reason that your expensive lubricants run the risk to get contaminated by dirt, water and other particulates. And even worse… your equipment get contaminated too. Since the smallest particulates can cause asset components to fail prematurely.

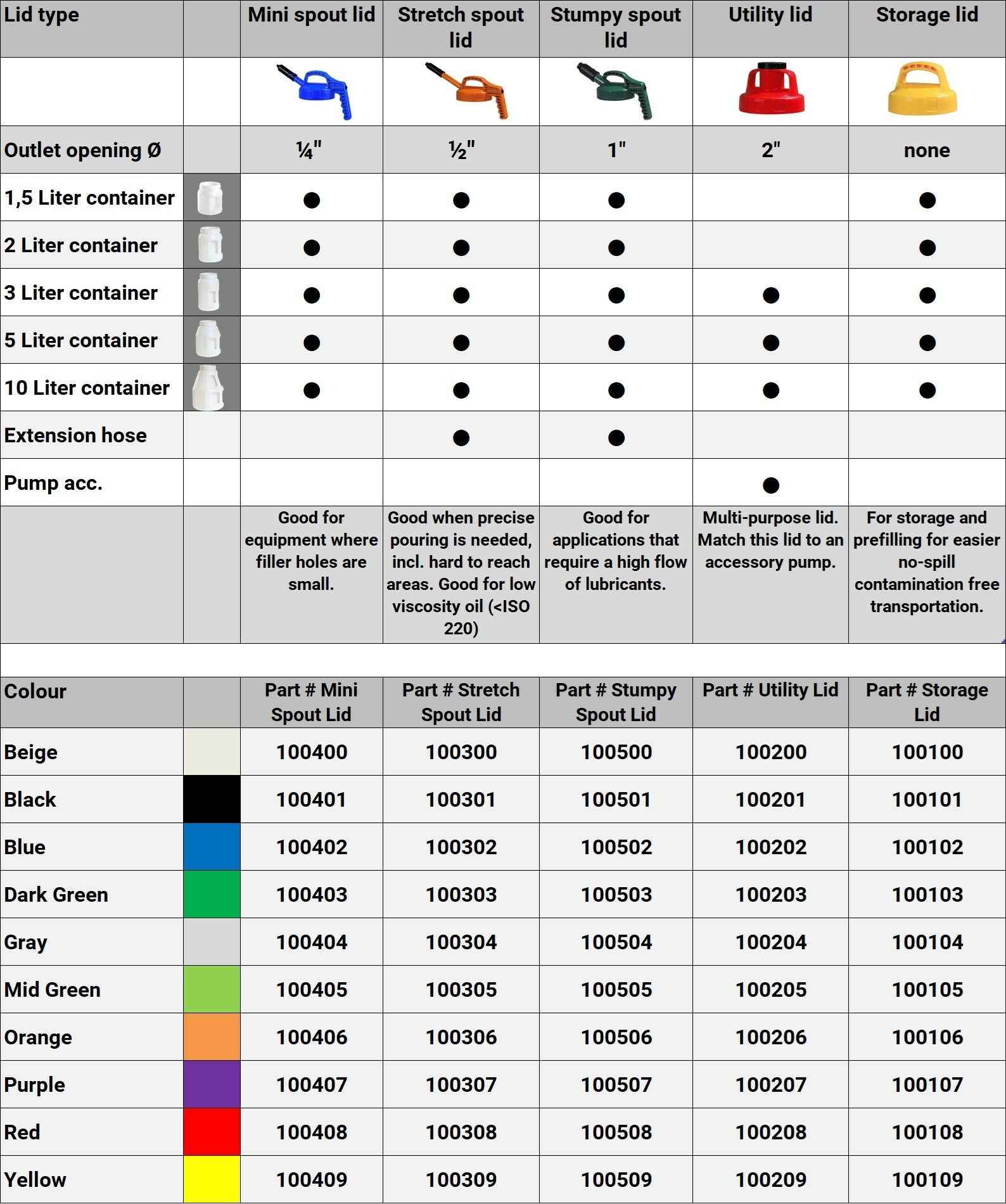

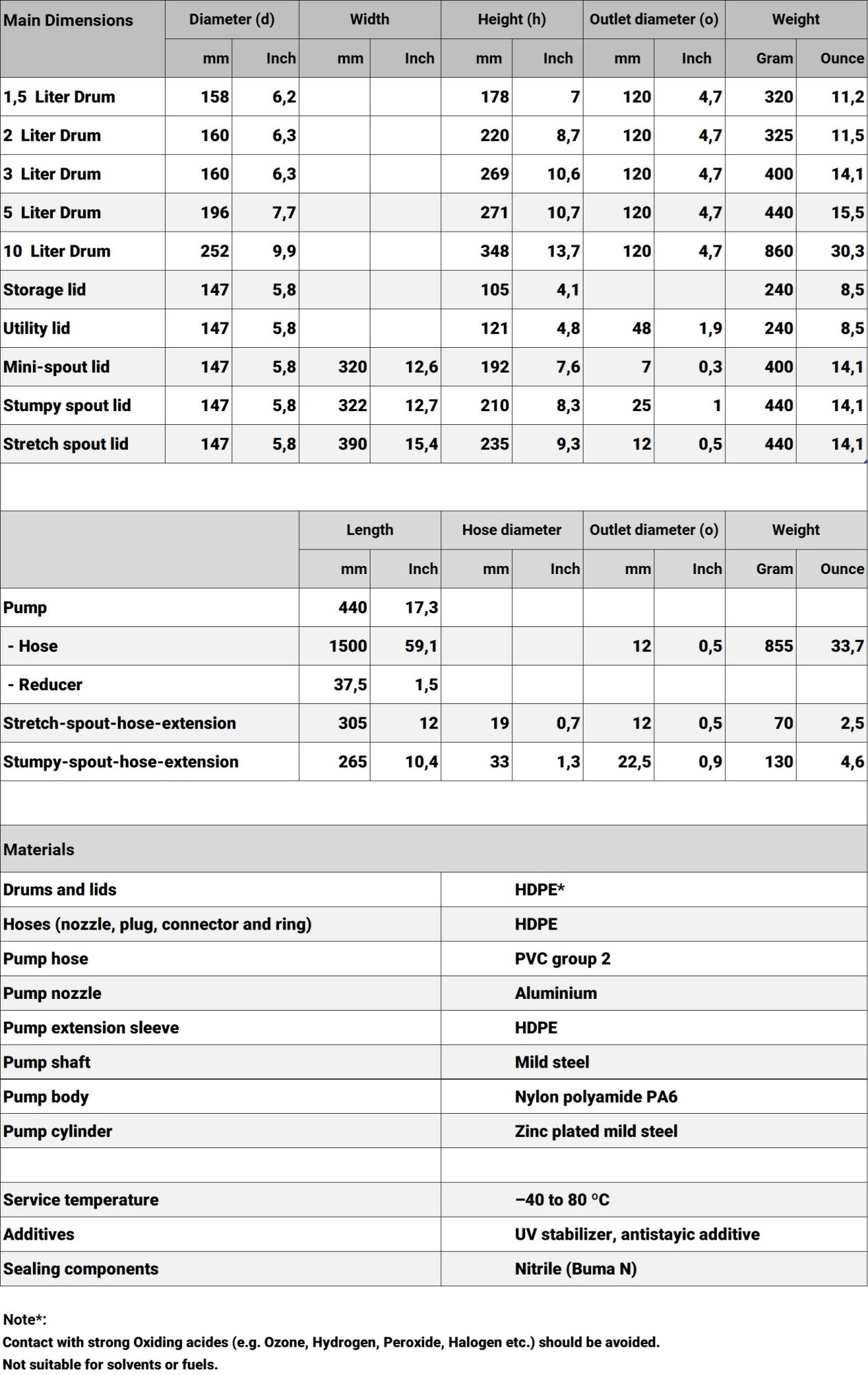

Fully sealing units are the solution to prevent contaminants from getting into the oil. Sealable, reusable oil storage containers are easy to dispense without the need for tools like funnels. Another recommendation is integrating a colour-coded system, which includes properly labeled containers to prevent cross contamination, so that contents are easily identifiable.