Grease Guns

Proper lubrication keeps everything in perfect working order!

Grease Guns are absolutely a necessity!

Which Grease Gun should be used when?

- If it's a well-maintained machine that just needs a couple of shots of grease a day, or a fitting in a hard to reach spot, the Pistol Grip Grease Gun is the way to go. A hand (pistol) type gun can get into tighter places.

- If the machine hasn't been greased in a while, sometimes you need the extra pressure of the Lever to get it moving. If it is going to take a lot of grease because it's dry, or the old grease is flushed out, the Lever Grease Gun is nice.

- Battery-operated Grease Guns are the ideal choice to lubricate large bearings or manual centralised systems (used to lubricate multiple bearings from a single lubrication point).

Grease Gun Assortment Line-Up

Pistol Grip Grease Guns

This heavy duty grease gun is ideal for one handed operation and is designed for use in confined spaces where access to grease fittings is restricted. The pistol grip is designed to prevent fingers from pinching and includes a soft rubber handle grip for comfort.

Provided with both a 4" steel extension and 12" flexible extension.

- 3-way packable (suction, cartridge or filler pump)

- Super strong pistol grip handle with soft rubber grip

- Pistol grip design prevents fingers from pinching

- Develops 5000 PSI / 345 BAR

- Available with steel and clear tubes in the 10 OilSafe colours

- Delivers 1 gm/stroke

Pistol grip grease gun

Available in the 10 well known OilSafe colours.

Pistol Grip grease gun

Heavy duty grease gun holder

Grease filler pump

• For grease u/i NLGI 2

• Designed for use with 25-50lb / 5 gallon grease pails

Lever Grease Gun

The hand lever guns are manually powered. They are able to build a decent amount of pressure This heavy duty, top of the line grease gun is designed for punishing day-in and day-out heavy industrial applications.

Provided with both a 6" steel extension and 12" flexible extension.

- 3-way packable (suction, cartridge or filler pump)

- Capacity for 14 oz (400gm) cartridges or will fit 500cc bulk filled

- 1/8" NPT threads

- Soft rubber grip for non-slip operation

- Delivers 1 gm/stroke

- Available with steel and clear tubes in the 10 OilSafe colours

Lever grease gun

Lever grease gun

Grease meter

Standard Grease Gun Holder

Manual Grease Guns are the best choice for low-volume greasing!

The Pistol Gun only needs to be used with one hand, while the Lever option requires both hands. Overall, however, the Lever Gun delivers more grease per stroke.

Benefits of using Grease Guns

Product longevity

Accuracy and Speed

Waste Prevention

Better saturation

Lightweight

Money Saving

Related document

FAQ Grease Guns

Why do I need to know the output per stroke of a Grease Gun?

The reason why you should know the output per stroke is that you need to know how much grease is added each time you lubricate a piece of equipment. The OilSafe grease guns deliver 1 gm/stroke. However, the actual output can vary depending on the age of the gun.

Which factors should I consider when establishing grease guns for my company?

Consider the following:

- The loading of the Grease Gun: cartridge, suction fill or bulk.

- Common lubrication quantities, i.e. high- or low-volume Grease Guns.

- Easy or difficult to reach lubrication points, i.e. pistol and/or lever grease guns; rigid or flexibel extension.

- Examine each application to determine the correct fitting and which style of grease gun and coupler is needed.

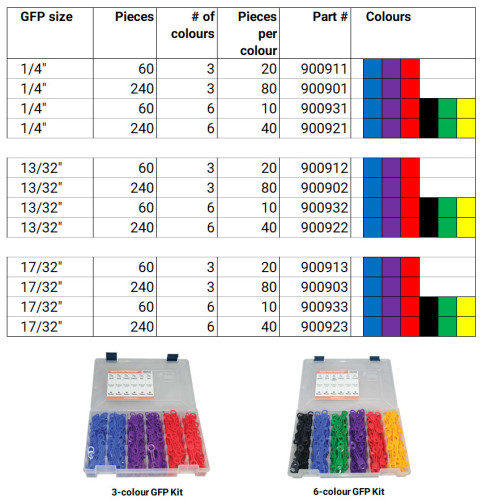

- Applying grease fitting protectors, enabling you to dedicate a specific colour to a specific grease.

-

Can you give me some hints for using a grease gun?

- Grease guns should be stored unpressurised and in a horizontal position (to avoid bleeding out of the grease) in a clean, cool and dry area.

- Calibrate grease guns regularly to ensure proper delivery volume.

- To ensure that contaminants are not introduced, use extreme caution when loading grease into the grease gun.

- When using/replacing cartridges, take care when removing the metal lid that no slivers are introduced to the grease.

- Clearly mark the grease gun in order to identify the grease with which it should be charged.

- Always clean the dispensing nozzle of the gun before using.

- Wipe fittings clean before applying grease.

- Clearly identify lubrication points with which grease it is to be used.

Why is priming required?

All grease guns require priming on first operation. It rids the grease gun of air, which can cause suction issues and prevent the grease gun from operating properly. It only takes a few seconds but ensures proper operation. Not priming a grease gun is usually the leading cause of issues with operation.

Can the electric grease gun be bulk filled with a grease cartridge, from a drum or with a pump?

Yes, all Oil Safe grease guns can be filled with grease cartridges, bulk filled from a pail/drum or with the use of a grease pump. The written instructions packaged with each electric grease gun illustrate these filling options.

Does the quick coupling work on metric grease zerks?

Yes. It automatically adjusts to grease zerk sizes, making connections quick and simple. When connected to a grease zerk, there is 6 points of engagement, so connections are secure and allow for hands free operation.

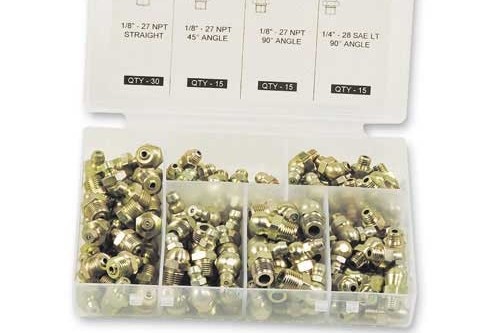

What to do when grease zerks get stuck or plugged?

Occasionally a grease zerk could get plugged or prohibits the flow of grease from a grease gun. OilSafe has many grease accessories for unplugging grease zerks, installing them, colour identification options and various sized grease zerks available in our catalogue.

Grease Fitting Protectors

Grease Fitting Protectors save you the cost of equipment failures

Explore the full Grease Equipment Assortment in our Webshop

More Products you might like

Flexible Grease Hose

Cartridge protection tube

SAE Grease Fitting Kit