Understanding the Role of Desiccants in Breathers

1. Introduction to Desiccant Breathers

Desiccant breathers are critical components in safeguarding equipment and systems from moisture and contaminants. At the core of their functionality lies the desiccant material, serving as the primary agent for moisture absorption.

2. Function of Desiccant in Desiccant Breathers

Within these breathers, desiccants act as potent absorbents, capturing moisture from incoming air streams. By effectively reducing humidity levels, desiccants prevent moisture-related damage to sensitive equipment components.

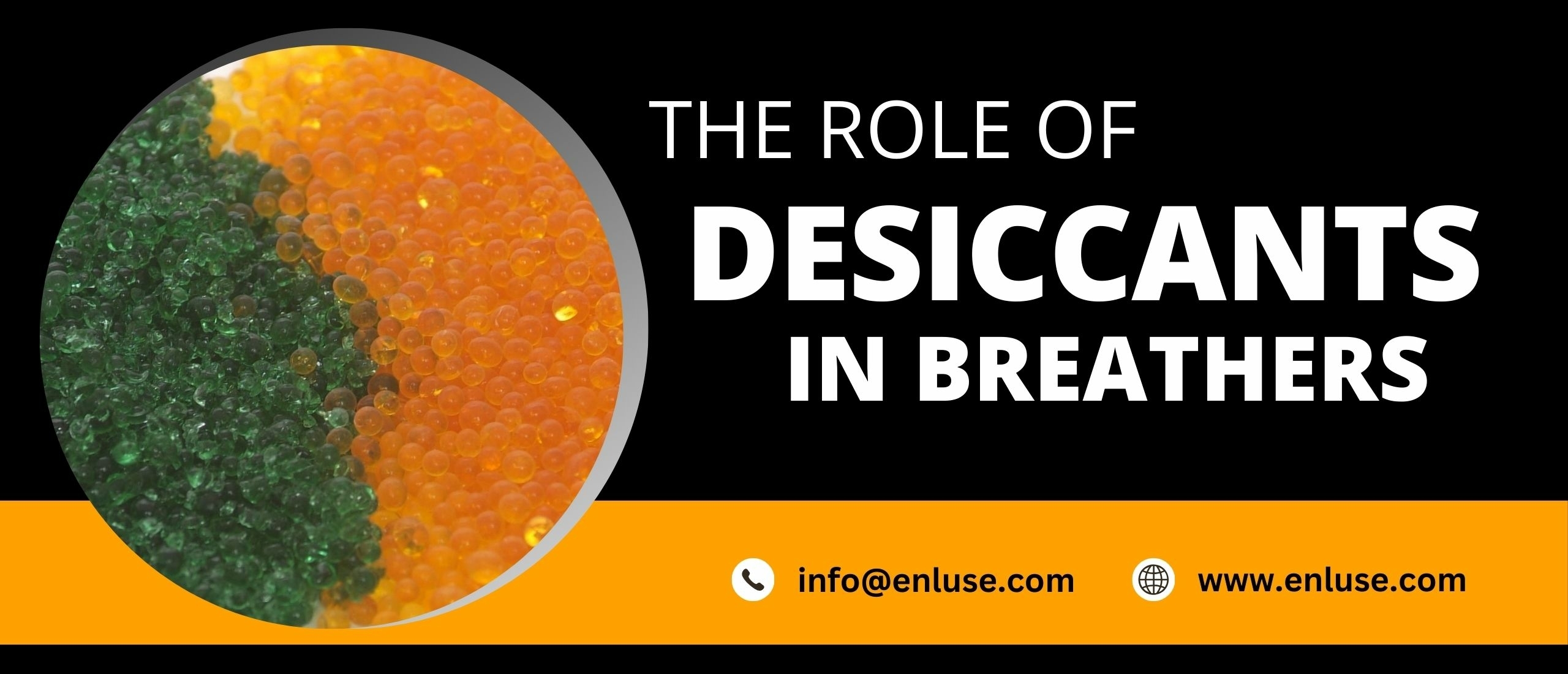

3. Types of Desiccant Materials

Desiccant breathers employ various desiccant materials, each tailored to specific environmental conditions and moisture absorption requirements. Variants such as silica gel, activated alumina, and molecular sieves offer distinct advantages in moisture control.

From Left to Right: Silica Gel, Molecular Sieve, Activated Carbon

From Left to Right: Silica Gel, Molecular Sieve, Activated Carbon

4. Operation Mechanism

Embedded within breather housings, desiccants intercept ambient air entering the system. Through adsorption, they capture moisture molecules, ensuring that only dry air permeates into the equipment or system.

5. Maintenance and Replacement

Regular maintenance is crucial as desiccants become saturated over time. Monitoring desiccant saturation levels and timely replacement or regeneration are vital for sustaining optimal moisture control.

6. Benefits of Desiccant Breathers

Desiccant breathers offer significant benefits, including enhanced equipment longevity, minimized downtime, and mitigation of corrosion risks. These advantages underscore the critical role of desiccants in preserving equipment integrity.

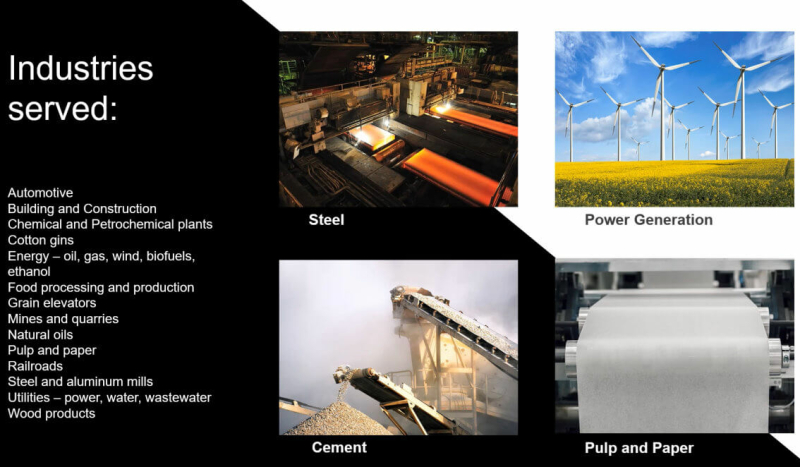

7. Applications and Industries

Desiccant breathers find widespread application across industries reliant on precision machinery and sensitive equipment. Hydraulic systems, gearboxes, transformers, and storage tanks are among the many applications benefiting from desiccant-based moisture control.

8. Conclusion

Desiccant materials within breathers are indispensable for mitigating moisture-related threats to equipment and systems. By absorbing moisture and maintaining optimal humidity levels, desiccants play a pivotal role in preserving equipment integrity and reliability. Proper selection, installation, and maintenance of desiccant breathers are imperative for sustaining peak performance and safeguarding critical assets.

Click here for more info on breathers