Why would you choose Enluse for oil analysis?

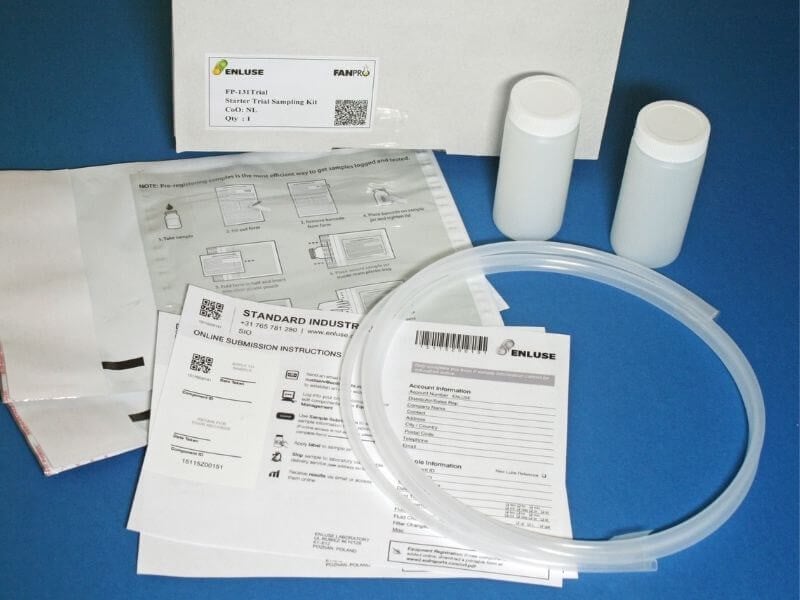

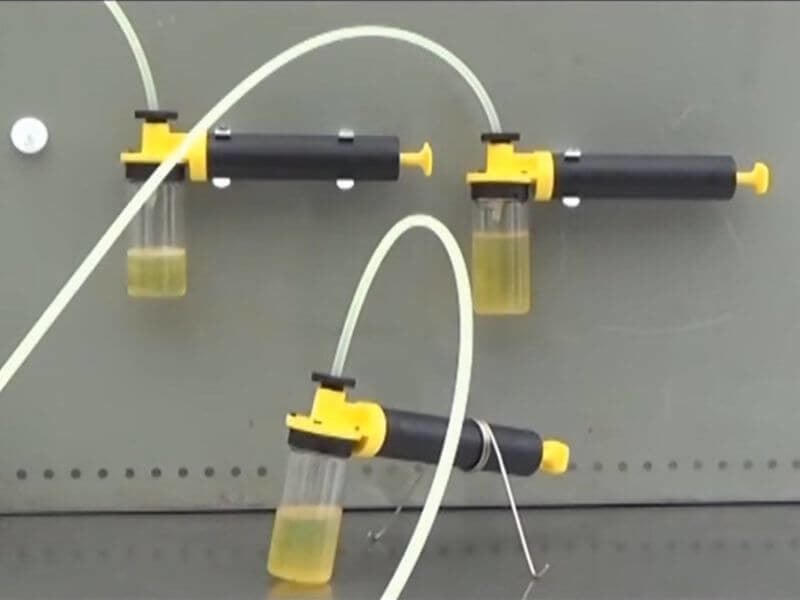

Oil Analysis is the litmus test for all the products and systems we supply. From the basic identification processes defining what oil goes in what equipment, how to dispense clean oil, what a best practice Lube room looks like, to what filtration processes and frequency is required. These are the basic fundamentals in the Enluse competency toolkit. Our Oil Analysis program (FanPro) gives us the knowledge to ensure none of the 6 lubrication rights are being missed.

The primary business objective with the Enluse Fanpro programme is to ensure that you receive speedy and correct information about the condition of your oil, a requirement needed to enact or achieve Best Practices in Lubrication Reliability. A Lubrication Reliability programme with a consistent, accurate monitoring of the oil is incomplete without ongoing field-to-lab oil analysis.

Enluse has oil analysis solutions to service your specific business needs, including FanPro Oil Analysis for engines or industrial equipment,.After consultation, we can recommend the right program to suit your needs.