The indispensable Oil Hand Pump

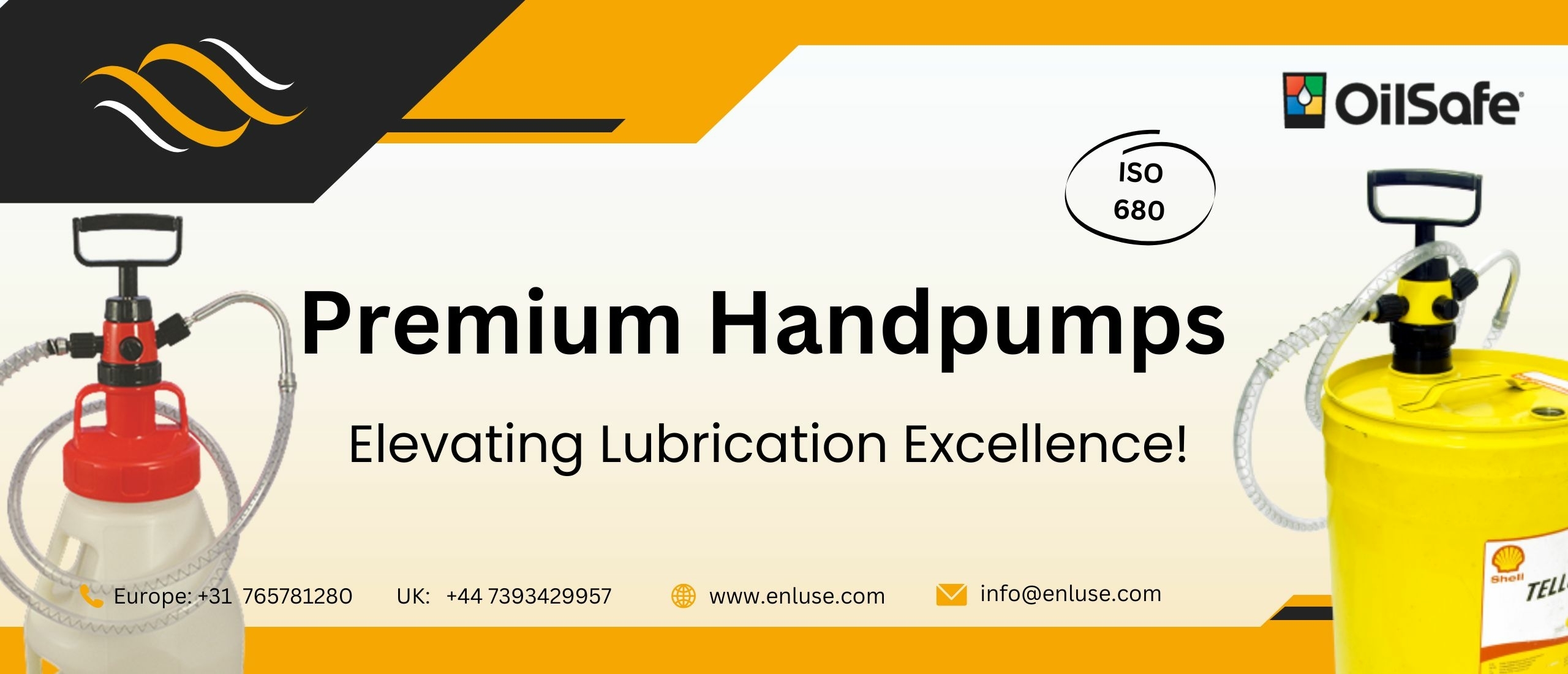

The OilSafe Premium Pump (heavy duty discharge pump) is a manually operated pump that is designed to handle the transfer of industrial lubricants and other fluids with a viscosity up to ISO 680 . It is a high volume pump that can deliver up to 1 liter per 12 strokes, and is suitable for use in a variety of applications, including bulk transfer and dispensing.

The pump is constructed from high-quality materials that are resistant to corrosion and wear, including a heavy-duty cast iron body and stainless steel spout. The pump is also designed with a built-in strainer to help prevent contaminants from entering the fluid during transfer.

The Premium Pump is easy to use and does not require any electrical power or compressed air to operate. Simply insert the suction tube into the fluid container, attach the pump to the container, and begin pumping the fluid. The pump's ergonomic handle (D-grip) and adjustable suction tube make it easy to control the flow of fluid and to reach into the container. For smaller fill hole applications a pump reducer nozzle accessory to the outlet nozzle can be added.

The Premium Pump is a reliable and durable pump that is designed to handle the transfer of high viscosity fluids. It is a cost-effective solution for industrial lubricant transfer and dispensing, and its high-volume capacity makes it ideal for larger-scale operations.

Premium hand pumps

Premium hand pumps

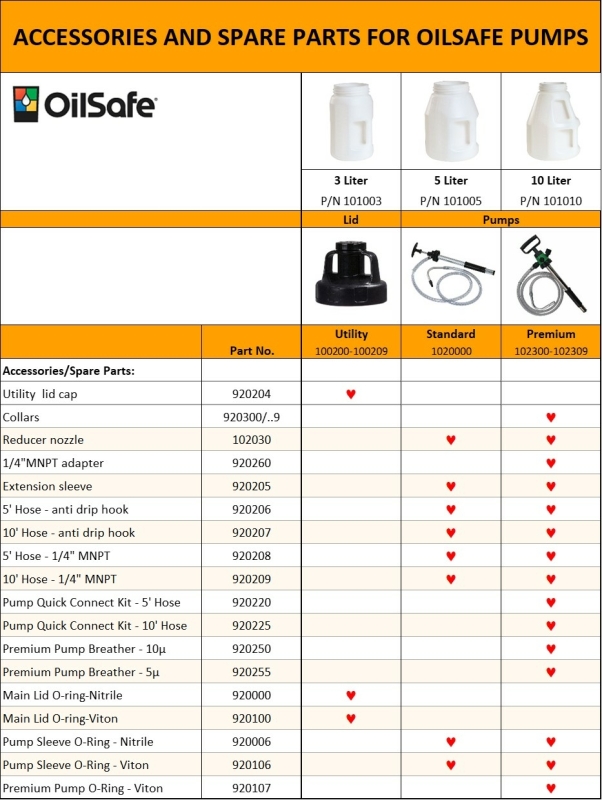

Pump Accessories and Spare Parts

Pump accessories and spare parts are essential components to keep pumps running efficiently and reliably. Here are some common examples of pump accessories and spare parts:

It's important to choose the right accessories and spare parts for your specific pump model and application to ensure proper performance and longevity.

Colour-coded Collars

The colour-coded collars of an OilSafe premium pump provide a variety of benefits in industrial lubricant handling and storage applications. Here are some of the benefits of using colour-coded collars on an OilSafe premium pump:

Easy identification:

The collars make it easy to identify different lubricant types, grades, and applications, allowing for quick and accurate matching of the pump to the correct lubricant. This helps reduce the risk of cross-contamination and lubricant mixing, which can result in costly equipment downtime and repairs.

Enhanced safety:

Using colour-coded collars on a premium pump enhances safety by reducing the risk of using the wrong lubricant or misidentifying lubricants. This helps prevent costly equipment damage and downtime, as well as reducing the risk of injury or accidents.

Efficient lubricant handling:

The colour-coded collars make it easy for operators to quickly identify and select the right pump for the job, which can improve overall efficiency and productivity. This can help reduce the time and effort required for lubricant handling.

Visual management:

The collars can be used as part of a visual management system to improve overall lubricant handling processes. This can help promote standardization, improve communication, and enhance overall process control.

Customizable:

OilSafe premium pumps can be customized with a range of colour-coded collars to suit specific lubricant handling requirements. This allows operators to tailor their lubricant handling processes to their specific needs and preferences.

Summarizing, the collars of a premium pump provide a range of benefits that enhance lubricant handling efficiency, safety, and process control. By making it easy to identify lubricants and match the pump to the correct lubricant, operators can reduce the risk of errors and enhance overall lubricant handling productivity.

Collars for the premium pump in

Collars for the premium pump in

the 10 OilSafe colours

Pump Reducer Nozzle

The pump reducer nozzles are a useful accessory for pumps used in high-pressure fluid delivery applications. They can help to increase the pressure of fluids delivered by a pump and direct lubricants to specific locations, making them an important tool in industrial and automotive lubricant handling systems.

The nozzle fits to the aluminum anti-drip discharge pipe on the outlet of the pump hose and reduces the outlet diameter down to approx. 1/4", making oil top offs to very small fill points easy, simple, fast and clean.

Pump reducer nozzle

Pump reducer nozzle

Extension sleeves for pumps

Extension sleeves for pumps are a useful accessory for lubrication systems that require precise and efficient fluid delivery to hard-to-reach locations. They can help reduce the risk of spills, improve access, and increase the efficiency of lubrication maintenance tasks.

The OilSafe pumps are provided with extension sleeves enabling the pumps to reach the bottom of a 10 Liter drum.

The replacement extension sleeves come standard with a nitrile O-Ring.

Pump Sleeve and O-ring

Pump Sleeve and O-ring

Premium Pump Breathers

Pump breathers are an essential component of a pump system that provides a passage for air to enter and exit the pump during operation. The breathers help to maintain the pressure balance in the pump and prevent contamination of the pumped fluid.

There are two types of pump breathers commonly used in industrial applications: baffle breather and trap breather.

Available in two different sizes these breathers screw into the accessory port on OilSafe Premium Pumps. The 10 micron baffle breather is simpler and less expensive than the 3 micron trap breather, but they are not as effective in preventing oil mist contamination.

Trap breathers, on the other hand, are more effective in preventing oil mist contamination but are more expensive and complex.

The choice between the two types of breathers depends on the specific application requirements and the level of contamination risk.

Premium Pump Breather

Premium Pump Breather

Adapter

Adapter and quick connects are components used in fluid handling systems to connect two or more pieces of equipment or fluid lines. They are designed to allow for easy and quick connection and disconnection, minimizing downtime and improving efficiency in fluid transfer operations.

The OilSafe premium pump uses a 1/4" male adapter. This brass fitting provides for secure and robust fitting of quick connects.

1/4" NPT adapter for use with OilSafe premium pump

1/4" NPT adapter for use with OilSafe premium pump

O-Ring Seals

O-rings are commonly used in hand pumps as they offer several advantages:

Sealing:

O-rings provide an excellent seal, preventing air or fluid leaks from the pump. This is crucial in hand pumps as it ensures that the pump is operating efficiently and effectively.

Durability:

O-rings are designed to withstand high pressure, abrasion, and wear, making them ideal for use in hand pumps. They can last for a long time without requiring replacement, saving you money on maintenance costs.

Resistance to temperature and chemicals:

O-rings can resist a wide range of temperatures and chemicals, making them suitable for use in harsh environments. They can withstand exposure to oil, gasoline, and other chemicals without becoming damaged or degraded.

Consider Viton O-ring seals for synthetic oils

where solvent content may be high.

Cost-effective:

O-rings are relatively inexpensive compared to other sealing options, making them a cost-effective choice for hand pump manufacturers and users.

Versatility:

O-rings come in various sizes, materials, and shapes, making them highly versatile. This means they can be used in a wide range of hand pump designs and applications.

O-rings offer many advantages for hand pump manufacturers and users, including excellent sealing, durability, resistance to temperature and chemicals, cost-effectiveness, and versatility.

Discharge hoses for pumps

Discharge hoses are an essential component of pumps used for on-site fluid storage and transportation applications. These hoses are designed to transfer liquids or fluids from the pump to the desired destination, such as a storage tank, a machine, or a transport vehicle.

They come in various sizes, lengths, and materials, depending on the specific application requirements. Some common materials used for discharge hoses include PVC, rubber, and polyurethane. These materials are selected based on factors such as the type of fluid being transported, the temperature, and the pressure requirements.

The size of the discharge hose is typically determined by the pump's flow rate and the distance the fluid needs to travel. A larger diameter hose can accommodate a higher flow rate and reduce friction losses, making it suitable for longer distances or higher volume applications.

A hose with an anti-drip hook outlet or 1/4" NPT male end is a type of fluid transfer hose that is commonly used in various applications, such as in automotive or industrial settings.

The anti-drip hook outlet is a feature of the hose that helps to prevent unwanted dripping of fluid after the hose has been disconnected from the source or destination. It is typically designed to be used with a manual or automatic shut-off valve that stops the flow of fluid when the hose is disconnected. This feature helps to prevent spills, waste, and contamination of the surrounding environment.

Hoses with anti-drip hook outlet and 1/4" MNPT end

Hoses with anti-drip hook outlet and 1/4" MNPT end

The 1/4" NPT male end refers to the size and type of connection on one end of the hose. The 1/4" refers to the diameter of the male end of the hose, and NPT (National Pipe Thread) is a standard thread type used in many fluid transfer applications. The male end is typically designed to be connected to a female NPT fitting on the source or destination of the fluid.

Overall, a hose with an anti-drip hook outlet or 1/4" NPT male end is a reliable and efficient option for fluid transfer applications that require a high degree of control and precision. The anti-drip hook outlet helps to prevent spills and waste, while the 1/4" NPT male end ensures a secure and compatible connection with the source or destination of the fluid.

In addition to size and material, other factors to consider when selecting discharge hoses include the hose's flexibility, durability, and resistance to abrasion, puncture, and kinking. It is also important to choose hoses that are compatible with the fluid being transported and any chemicals or additives that may be present.

Discharge hoses play a critical role in on-site fluid storage and transportation applications, as they ensure the safe and efficient transfer of fluids from the pump to the desired destination. It is important to choose the right hose for the specific application to ensure optimal performance, safety, and longevity.

Note:

The premium and standard OilSafe pump come standard with a 1,5m anti-drip outlet discharge hose.