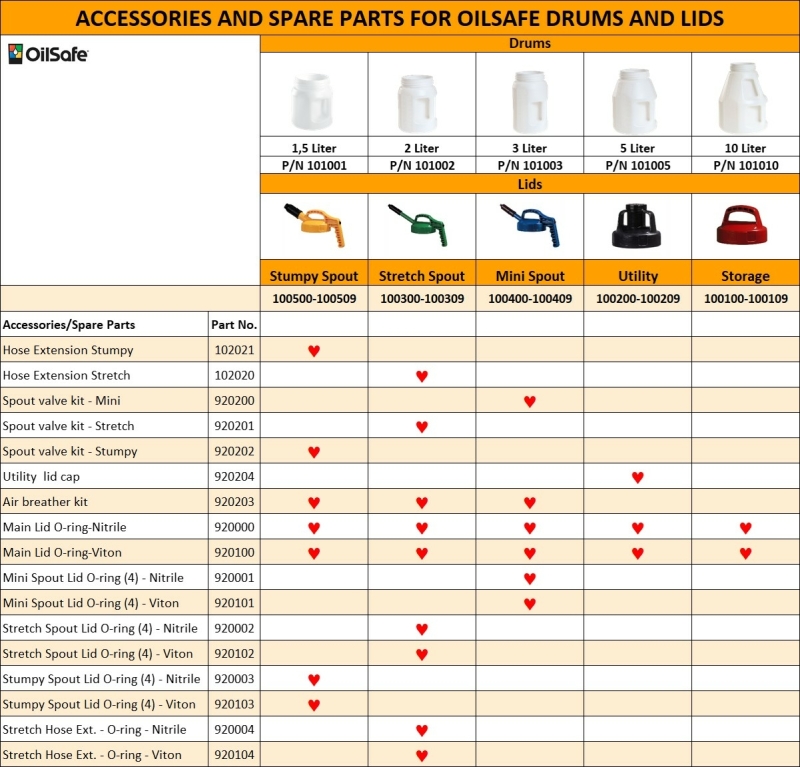

Oil drums and accessories

Accessories and spare parts are important for OilSafe drums and lids because they help to ensure safe, efficient, and accurate dispensing of fluids. Here are some reasons why accessories and spare parts are so important.

Improved Efficiency

Accessories such as pumps and hoses can help to improve the efficiency of the fluid transfer process. These accessories are designed to work seamlessly with OilSafe drums and lids, reducing the risk of spills, leaks, or other mishaps.

Better Accuracy

Accessories such as spout hose extensions, colour-coded collars, and pump reducer nozzles can help to ensure accurate dispensing of fluids. This is important when working with oils, lubricants, or other fluids that need to be dispensed in precise amounts.

Longer Lifespan

Spare parts such as o-rings, pump extension sleeves, and spot valve kits can help to extend the lifespan of OilSafe drums and lids. These spare parts are designed to replace worn or damaged components, helping to keep the drums and lids in good working order.

Reduced Maintenance Costs

By using high-quality accessories and spare parts, you can help to reduce the maintenance costs associated with OilSafe drums and lids. Regular maintenance and replacement of worn or damaged components can help to prevent costly repairs or replacements down the line.

Recommended guidelines for handling oil containers:

- Opt for oil cans and top-up containers that ensure an airtight seal.

- Always securely reseal containers after each use.

- Avoid the use of galvanized containers.

- Designate specific containers for "mixable lubricants only" and clearly label them accordingly.

- Refrain from storing oil-filled top-up containers near machines; instead, place them in a nearby locker or cabinet.

- Regularly inspect containers for any accumulation of dirt, sludge, or debris.

Accessories and Spare Parts

Spout Hose Extensions

Stumpy and Stretch Spout Hose Extensions are products designed to extend the reach of Stumpy and Stretch Spout Lids.. These hose extensions are typically made of flexible materials like plastic or rubber, and they attach to the end of your spout with a threaded connection.

Stumpy Spout Hose Extensions are short, compact extensions that are designed for use in tight spaces. They typically extend the reach of your spout by a few cm's, making it easier to reach fill points..

Stretch Spout Hose Extensions, on the other hand, are longer and more flexible than Stumpy extensions. They can extend the reach of your spout by several cm's, making them ideal for use in hard to reach or awkward fill points.

Both Stumpy and Stretch Spout Hose Extensions are relatively easy to install and can be a great way to make your stumpy or stretch spout lid more versatile and convenient to use. However, it's important to make sure that you choose the right extension for your needs.

More details about Spout Hose Extensions

Spout Valve Kits

Spout valve kits for OilSafe lids are accessories designed to help dispense fluids safely and cleanly from OilSafe containers. These kits typically include a spout valve, a spout extension, and a cap that fits securely onto the container.

The spout valve is designed to control the flow of fluid from the container, allowing you to dispense it in a precise and controlled manner. The spout extension helps to direct the flow of fluid away from the container, reducing the risk of spills and splashes.

The twist top spouts on OilSafe lids provide for secure sealing of the containers and make it easy to get the lid into position for pouring without spills and contamination. The spout valve can be closed tightly when not in use, preventing dirt and other debris from entering the container. Additionally, the extension helps to direct the flow of fluid into the target spot, reducing the risk of spills and splashes.

Spout valve kits are typically easy to install and can be used with a wide range of fluids, including oils, and lubricants. They can be particularly useful in industrial and manufacturing settings where fluids need to be dispensed safely and accurately.

When selecting a spout valve kit for your OilSafe lid, it's important to choose a kit that is compatible with your specific container size and type. Additionally, you may want to consider factors such as the viscosity of the fluid you'll be dispensing and the frequency of use.

Replacement Spout Valve Kits are available for the Mini, Stretch and Stumpy spout lids, and come with Nitrile O-Rings.

Utility lid cap

A utility cap replacement for OilSafe utility lids is an accessory designed to replace the original cap on your OilSafe utility lid. This cap is typically used to seal the utility lid when it's not in use, helping to prevent dirt, debris, and other contaminants from entering the container.

Air breather kit

The air breather button on OilSafe spout lids is an important component that helps to regulate air pressure inside the container during use. If the air breather button becomes damaged or stops working properly, it can lead to issues with fluid dispensing and may even damage the container.

Air Breather Kit - 920203

Air Breather Kit - 920203

To replace the air breather button on your OilSafe spout lid, follow these steps:

- Remove the old air breather button: Use a screwdriver or other tool to carefully pry the old air breather button out of the spout lid. Be sure to take note of the orientation of the button so that you can replace it correctly.

- Clean the area: Once you've removed the old button, use a clean cloth or towel to wipe the area around the button clean. This will help to ensure a good seal when you install the new button.

- Install the new air breather button: Take the new air breather button and align it with the opening in the spout lid. Press the button firmly into place, making sure that it is seated securely.

- Test the button: Once the new air breather button is installed, test it to make sure that it is working properly. You should be able to feel air moving through the button when you press on it.

Replacing the air breather button on your OilSafe spout lid is a relatively simple process that can be done with just a few basic tools.

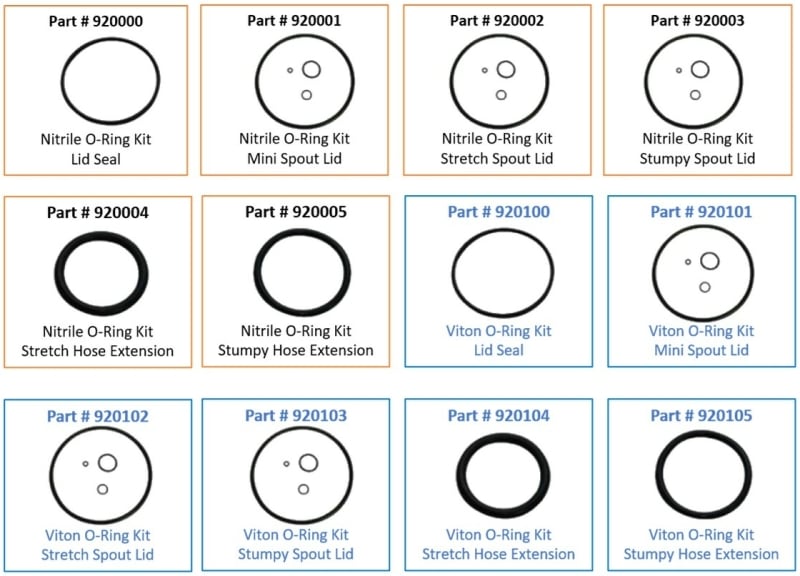

O-rings

O-rings are important components of OilSafe transfer containers that help to create a tight seal between the container and the cap or spout. Over time, O-rings can become worn or damaged, which can lead to leaks and other issues.

Replace OilSafe equipment seals with pre-configured O-ring kits

Replace OilSafe equipment seals with pre-configured O-ring kits

To replace the O-ring on your OilSafe transfer container, follow these steps:

- Remove the old O-ring: Use a small tool or your fingers to carefully remove the old O-ring from the container. Be sure to clean any debris or residue from the area where the O-ring was located.

- Measure the O-ring: Use a ruler or caliper to measure the diameter of the O-ring. This will help you choose the correct replacement size.

- Choose a replacement O-ring: O-rings are available in a variety of sizes and materials. Choose a replacement O-ring that matches the diameter of the old O-ring and is made of a compatible material.

- Install the new O-ring: Take the new O-ring and carefully stretch it around the area of the container where the old O-ring was located. Be sure to seat the O-ring properly and make sure that it is evenly distributed around the container.

- Test the seal: Once the new O-ring is installed, test the seal by screwing the cap or spout onto the container and checking for leaks. If there are no leaks, the new O-ring should be properly installed.

Replacing the O-ring on your OilSafe transfer container is a simple process that can help to prevent leaks and ensure that your fluids remain properly contained. Be sure to choose a replacement O-ring that is compatible with your specific container to ensure proper fit and function.

All OilSafe products, except the Premium Pump, come standard

with Nitrile O-rings.

Nitrile O-rings and Viton O-rings are both commonly used in OilSafe equipment as they offer good chemical resistance, durability, and sealing capabilities. However, there are some differences between the two materials that should be considered when selecting O-rings for your OilSafe equipment.

Nitrile O-rings are typically made from synthetic rubber and are commonly used in applications that involve petroleum-based fluids, such as oil and gasoline. They offer good resistance to oils, fuels, and some chemicals, making them a good choice for many OilSafe applications. Nitrile O-rings are also relatively inexpensive and widely available.

Viton O-rings, on the other hand, are made from a type of synthetic rubber known as fluoroelastomer. They offer excellent resistance to a wide range of chemicals, fuels, and oils, making them a good choice for applications that involve harsh or corrosive fluids. Viton O-rings are also more heat-resistant than nitrile O-rings and can withstand temperatures of up to 400°F (204.4℃).

When selecting O-rings for your OilSafe equipment, it's important to consider factors such as the type of fluid being used, the temperature range of the application, and the expected lifespan of the O-ring. Nitrile O-rings may be a good choice for many applications, while Viton O-rings may be necessary for more demanding applications involving harsh or corrosive fluids.

It's also important to select O-rings that are properly sized and compatible with your specific OilSafe equipment to ensure a proper seal and prevent leaks.

Accessories and spare parts are important for OilSafe drums, because they help to ensure safe, efficient, and accurate dispensing of fluids, extend the lifespan of the equipment, and reduce maintenance costs.