Lustor - the start of your Reliability journey

A bad lubricant storage can result in poor performance, increased wear and tear on machinery, and costly repairs or replacement. It's important to ensure that lubricants are stored in clean, sealed containers

Have you ever been in plants which look like this?

Certainly our lubricant storage is probably the very first thing where your reliability journey takes off. Having a clean, safe, and visually appealing store system certainly contribute to a company's commitment to the reliability journey. A clean and organized store system contribute to operational efficiency and reduce the risk of accidents or injuries.

Every time oil is transferred to a new container or piece of equipment, contamination normally doubles unless steps are taken to protect the oil.

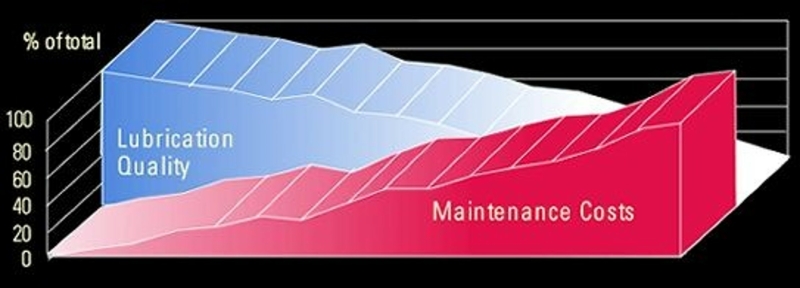

There is a direct correlation between lubrication quality and maintenance costs.

- Poor lubrication can lead to increased wear and tear on machinery, which can result in breakdowns, reduced efficiency, and ultimately, higher maintenance costs.

- When lubrication quality is poor, it can cause friction, heat, and wear between moving parts, which can lead to premature failure of the equipment.

- In addition, poor lubrication can result in the formation of deposits and contaminants, which can further damage the machinery.

Correlation between Lubrication Quality and Maintenance Costs

Correlation between Lubrication Quality and Maintenance Costs

On the other hand, high-quality lubricants help reduce friction and wear, which can extend the life of the equipment and reduce the need for repairs and maintenance.

Regularly scheduled lubrication maintenance can also help detect potential issues early and prevent costly repairs in the long run.

Overall, investing in high-quality lubricants and maintaining proper lubrication practices help reduce maintenance costs and extend the life of your equipment.

Lustor - Lubrication Storage System

Lustor is a brand of lubrication storage systems that are designed to help users properly store and dispense lubricants for their machinery and equipment. These systems are often used in industrial and manufacturing environments, where the proper use of lubricants can have a significant impact on equipment performance and longevity.

The Lustor lubrication storage system typically consists of a container, which is used to store the lubricant, and a dispensing system that allows users to easily and accurately apply the lubricant to their equipment. The system is designed to prevent contamination and waste, which can be a major concern when working with lubricants.

One of the key features of Lustor lubrication storage systems is their ability to provide a closed loop system for dispensing lubricants. This means that the lubricant is never exposed to the environment, which can help to prevent contamination from dust, dirt, and other particles. Additionally, the system is designed to dispense the exact amount of lubricant needed, which can help to reduce waste and ensure that the equipment is properly lubricated.

Available models

Three different system configurations are offered to fit your application needs and requirements:

The wall mounted unit, which actually uses the 55 gallon drum as a reservoir. This is great for plants that maybe only have one or two lubricants. Or maybe you have satellite locations within your facility that use a very small amount of oil. All the same features still apply to the wall mounted unit as in the tank units.

And the 125 and 250 Liter Units.

Key features of the Lustor systems:

- Impact resistant poly tanks .

- Heavy-duty pneumatic pump (3:1 air/oil pump).

All the pumps on the inside are pneumatic. So that makes these systems very universal across the world. - Three-way filtration (10-micron filter).

In order to be sure that we were filtering oil as it entered the tank, then kidney loop and recirculate that oil, and also it is filtered before it's dispensed. - Oil-consumption meter.

A meter that will measure the consumption of the oil or dispensed out of that system. So for anyone that is wanting to measure how much lubricant is used in a shift or a change out or over a certain period of time, this would be a great tool that you want to consider. - Oil level indicator.

All of the tanks have three oil level indicators. These are site glasses that are molded into the side of the Poly Tank. So you'll be able to identify when you need to refill those tanks. And if you need to fill it with half a drum or a full drum. - Auto shut-off dispensing tap.

- Drip tray

On the bottom there's a drip tray to place your OilSafe containers. - Drum transfer hose kit

It also comes with its dedicated drum transfer kit. This is a stinger that will transfer the oil from the 55 gallon drum into the tank. And it is dedicated so we don't cross contaminate. - Desiccant breather

An Air Sentry filter that protects the head space, keeping it clean and dry.

Benefits

The main benefit: Lustor is very cost effective. Anyone that has projects that may need to be implemented tomorrow, or something that may not need to go through a budget process, this is something that could really help them get started.

All these units are already pre-assembled and fabricated,

so they are in stock, ready to be shipped.

Benefits

- Cost-effective

- Organized and clean work-space

- Increases work environment safety

- Prevents cross-contamination

- Improves lubricant quality

- Lowers lubricant and maintenance costs

- Less equipment downtime

- Increase productivity

System dimensions

Filtration Modes

In terms of the three-way filtration, we want to filter the oil before it goes into the tank.

Fill Mode (1)

Lift up the yellow cover.

Connect the suction hose into the drum

connect the ISOb quick connect

the system would be switched into fill mode.

and the pump will start and filter the oil across your filter and then dispense it back into the tank.

Re-circulation Mode (2)

Once the oil is completely uploaded. the lever can be put in the down position and this will be a re-circulation mode.

If you would want to do further kidney loop, that oil to be a certain ISO cleanliness code, you can certainly do that. The pump that is installed is a three to one pump. The lighter viscosity side of things you're looking at about three gallons a minute, so with about 55 gallons, you're probably looking at about two hours to get about seven passes across that filter.

Dispense Mode (3)

The third mode is dispensing. So nothing really changes on the first two valves. The third valve would change to dispense of the tap and not go back to the tank, and then you'll be able to dispense it out of the tap because it is pneumatic. As soon as that tap is depressed or opened fluid would dispense and the pump will automatically turn on. Once the tap is released or stopped, the pump will shut it off.

Boost your Lube Room

To further minimize cross-contamination when storing and transferring lubricants, match your Lustor Lubrication Storage System with a dedicated OilSafe colour-coded transfer container, drum label kit and fluid identification labels.

Conclusion

Our journey to maintain clean oil in our industrial machines has reached its successful conclusion. By investing in regular maintenance and ensuring the cleanliness of oil, we have reduced machine downtime and increased operational efficiency. This has translated into cost savings, improved productivity, and enhanced reliability.

We recognize that the reliability journey is an ongoing one, and we remain committed to sustaining our efforts to ensure the continued smooth operation of Lustor.

As we move forward, we will continue to monitor the performance of our lubrication storage systems and make any necessary adjustments to our maintenance practices. By doing so, we can ensure that our systems remain a reliable and efficient asset, contributing to success for years to come.