Labeling Evaluation Kit

The OilSafe Labeling Evaluation Kit is a tool that allows for on-site evaluation of the visual lubricant labeling system developed by OilSafe. This kit is designed to provide users with a first-hand experience of the labeling system and help them understand how it works and how it can benefit their lubrication program.

The kit includes a variety of OilSafe labels and label holders that can be used to label lubricants and equipment, as well as an evaluation guide that outlines the key features and benefits of the OilSafe labeling system. The guide provides instructions for evaluating the labels and assessing their effectiveness in improving lubrication program efficiency, reducing downtime, and preventing costly mistakes.

Labeling Evaluation Kit - part # 290001

Labeling Evaluation Kit - part # 290001

By using the Labeling Evaluation Kit, you can gain a better understanding of the benefits of the OilSafe labeling system and how it can improve your lubrication program. You can also evaluate the labels in real-world situations and determine if they meet their specific needs and requirements.

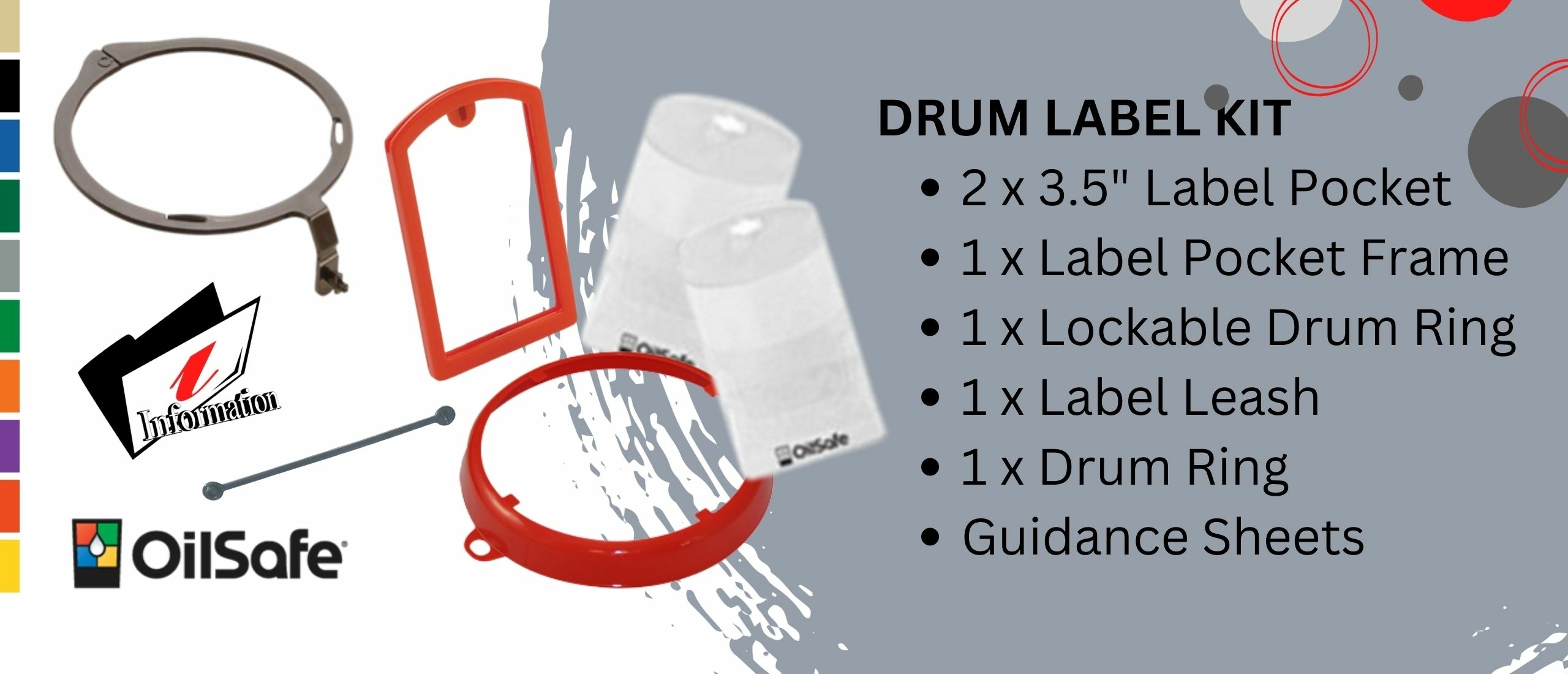

Kit includes

| Description | Pieces |

| Label Pocket Frame | 3 pcs of all 10 colours |

| Label Pocket (Small) | 10 pcs |

| Label Pocket (Large) | 10 pcs |

| Lockable Drum Ring | 6 pcs |

| Label Leash - Pack of 10 | 1 pack |

| Label Magnets - High Strength | 24 pcs |

| ID Washer Label Clamp | 6 pcs |

| Label Wrap | 1 pc |

| Content Label Water Resistant 2"x3.5" | 10 sheets |

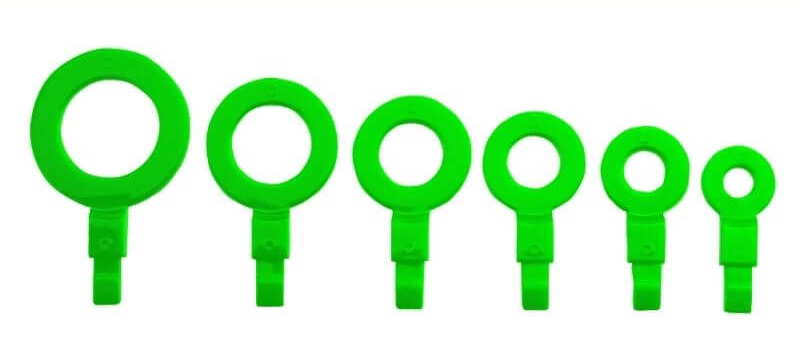

| 1/8" BSP- ID Washer Yellow | 4 pcs |

| 1/4" BSP- ID Washer Blue | 4 pcs |

| 3/8" BSP- ID Washer Red | 2 pcs |

| 1/2" BSP- ID Washer MidGreen | 2 pcs |

| 3/4" BSP- ID Washer Purple | 2 pcs |

| 1" BSP - ID Washer Black | 2 pcs |

The Labeling Evaluation Kit is a valuable tool for anyone who is interested in implementing the OilSafe labeling system in his/her lubrication program or wants to learn more about the system and its benefits.

Label Pocket Frames

Label Pocket Frames

Benefits

The labeling system offers several benefits for lubrication programs, including:

- Improved efficiency: The visual labeling system enables faster and more accurate identification of lubricants and equipment, reducing the time needed for maintenance and lubrication activities.

- Reduced downtime: The use of clear and visible labels reduces the risk of mistakes and equipment failures due to incorrect lubrication, resulting in fewer unscheduled downtime events.

- Enhanced safety: The system includes colour-coded labels that enable easy identification of lubricants and their associated risks, enhancing safety for personnel working with lubricants.

- Increased reliability: The system promotes best practices in lubrication and maintenance, ensuring that lubricants are used correctly and equipment is maintained to a high standard, leading to increased reliability and longer equipment life.

- Improved inventory management: The system includes customisable labels that enable easy tracking and management of lubricant inventory, reducing the risk of stockouts or overstocking.

- Compliance with industry standards: The OilSafe labeling system is designed to comply with industry standards and regulations, ensuring that lubrication programs meet the necessary requirements.

Fill point ID washers (Size: 1", 3/4", 1/2", 3/8", 1/4", 1/8" BSP)

Fill point ID washers (Size: 1", 3/4", 1/2", 3/8", 1/4", 1/8" BSP)

Overall, the OilSafe labeling system offers a comprehensive and effective solution for lubrication program management, helping to improve efficiency, reduce downtime, enhance safety, increase reliability, and ensure compliance with industry standards.