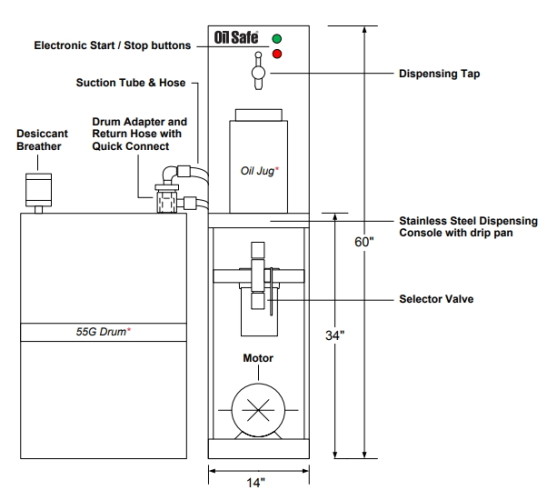

The OILSAFE® 55 Gallon Drum Work Station is designed to store and dispense machinery lubricating oils and other non-volatile fluids up to ISO 680. The storage of fluids with a flashpoint below 150°F (65.5°C) is strictly prohibited. This unit delivers best practice contamination control for 55 gallon drums.

The 55 gallon drum work station features:

- a stainless steel dispensing console and drop pan,

- dedicated suction hose,

- a pump/filter providing 2-way filtration (filters while dispensing and circulate (kidney loop)

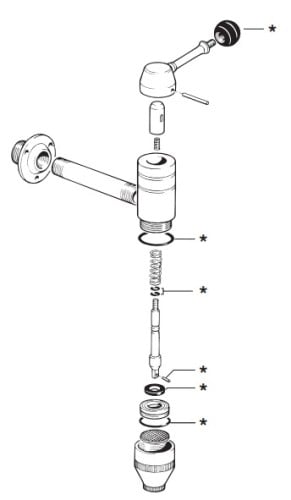

- a pressurised dispensing tap.

The 55 gallon work station in use