The Oil analysis programme always starts with the understanding of the machine reliability. In other words, it provides a valuable insight in your oil lubricated equipment. The programme includes:

- Monitoring of the condition of the oil

- Monitoring of the condition of the equipment

- Proactively monitoring harmful contaminants within the oil

Not all equipment need to be part of the oil analysis programme. Focus on the critical equipment (f.i. because of high capital cost, high repair expenses, many failure problems etc.). Before taking samples you should first take a good baseline of the current oil condition of the equipment, failure rates and costs.

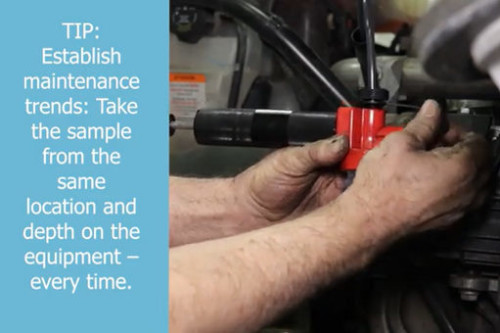

The last steps before taking oil samples are:

- lay down sampling procedures (How to obtain proper samples)

- select sampling locations per equipment

- determine the sampling frequency