Optimising Lubricant Management in Food and Beverage

Understanding the Importance of Lubricant Application

Welcome to our latest blog post, where we delve into essential practices for storing and handling food grade lubricants. This article serves as a comprehensive guide sourced directly from the video below. Whether you're a maintenance professional in the food industry or simply curious about best practices, this blog post is packed with valuable tips to ensure the safety and efficiency of lubrication practices in food processing plants.

Food Industry

Food Industry

In today's exploration, we delve into a pressing concern prevalent in various industries, especially within food and beverage companies: the meticulous application of lubricants. Emphasising the criticality of abiding by regulations and guidelines to ensure product safety, this discussion underscores the necessity of using appropriate lubricants in designated areas. Contamination looms as a significant threat in food production, highlighting the importance of precision in lubricant selection and application.

Ensuring the Safety of Food-Grade Lubricants

Ensuring the safety of food-grade lubricants is paramount. They must possess attributes like odorlessness, colourlessness, and harmlessness upon incidental contact.

However, selecting the suitable lubricant is only the initial step; proper application by technicians is equally imperative to thwart cross-contamination.

Such negligence not only jeopardises the lubricant's integrity but also compromises machinery and, consequently, product quality.

Proper application by technician

Proper application by technician

Implementing Effective Storage and Handling Practices

Implementing effective storage and handling practices emerges as a pivotal strategy.

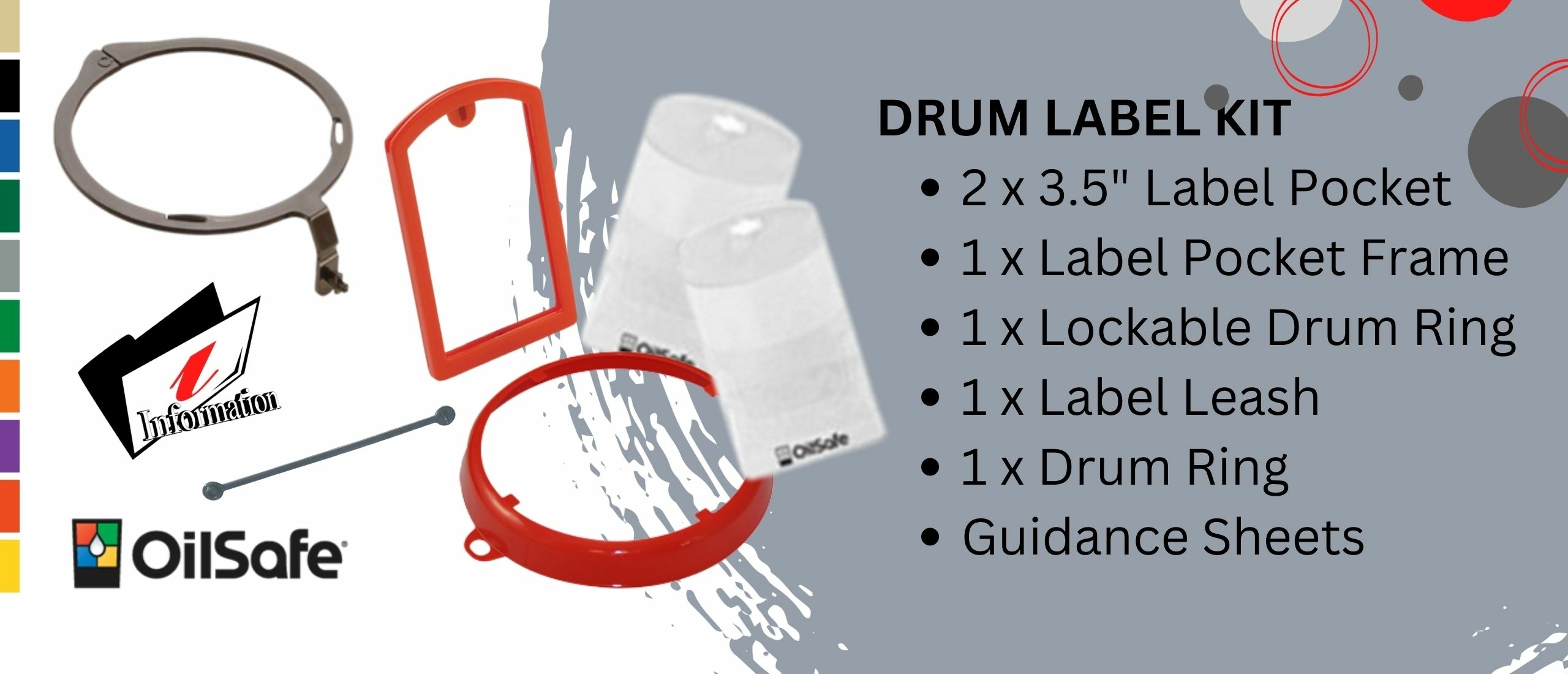

- Clear labeling and segregation of food-grade and non-food-grade lubricants play a pivotal role in risk mitigation.

- Utilising top-up containers, grease guns, and other storage solutions can significantly streamline operations. These containers, often colour-coded and labeled, offer a reusable and sustainable approach to lubricant management.

- Moreover, incorporating visual cues beyond colour, such as shapes, ensures accessibility for individuals with colour vision deficiencies.

Lubricant Management in the Food industry

Lubricant Management in the Food industry

Understanding Precise Lubricant Application

Understanding where food-grade lubricants are essential in the production line is crucial. While H1-lubricants are necessary directly over food processing lines, areas further away may require H2-lubricants . Balancing these lubricant types ensures both safety and operational efficiency.

Conclusion: Fortifying Lubrication Processes

Proper storage and handling of food grade lubricants are crucial aspects of maintenance and safety in food processing plants. By implementing the tips and strategies outlined in this guide, you can optimise lubrication practices, minimise contamination risks, and ensure compliance with industry regulations. Thank you for joining us on this journey to maximise safety and efficiency in food grade lubrication.

We recommend you to watch the video below. In the video, lubrication expert Wes Cash (Noria) provides invaluable insights into the critical aspects of storage and handling for food grade lubricants. With years of experience in the field, Wes shares practical tips and expert advice to help professionals maintain the quality, prevent contamination, and comply with industry regulations when dealing with food grade lubricants.