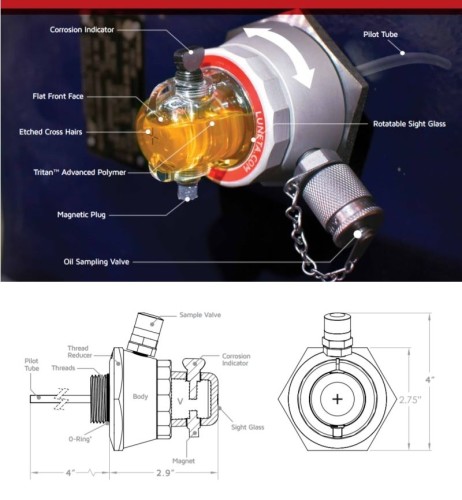

The Condition Monitoring Pod (CMP)

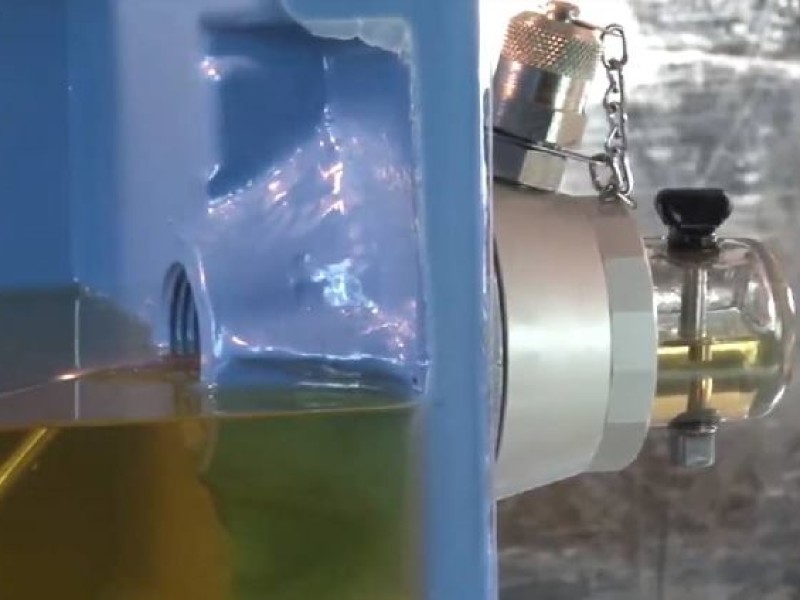

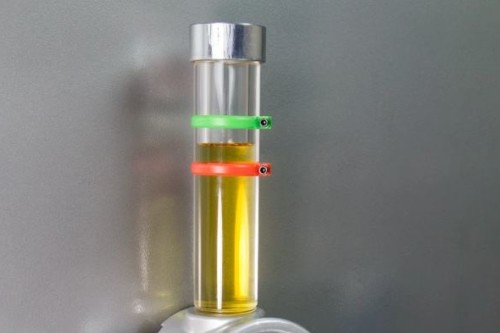

The CMP is an all-in-one oil sight glass thanks to their multi-use functions. It has a 3D sight glass for checking the oil level, colour and clarity. It also includes a visible magnetic plug inside the glass to capture wear debris and make it easily visible. A built-in sampling valve with an attached pilot tube for live-zone oil sampling. The CMP is made of Tritan co-polyester.

It includes:

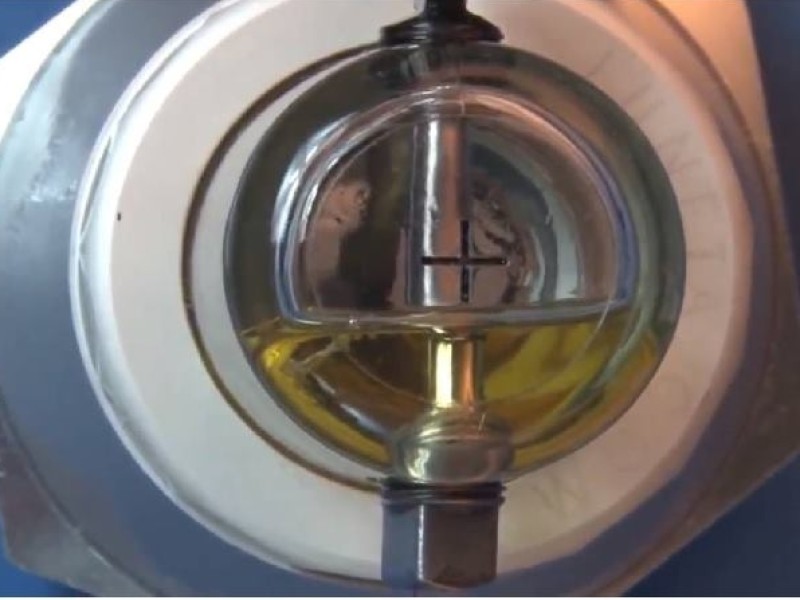

a 3D sight glass offering a 360-degree view (for checking colour and clarity, oil level and foaming, wear debris or corrosion),

a built-in oil sampling port (with attached pilot tube for live-zone oil sampling),

an easy-to-remove magnetic plug (to capture wear debris and make it easily visible),

a corrosion/ varnish inspection probe,

and quick lubricant access point for syringe sampling.

Early Fault Detection

Early detection of machine faults and abnormal wear is key machine reliability. The failure development period begins with ”P”, the point of first detection, and ends with “F”, the state of operational failure. The longer the PF interval the greater the likelihood a failure can be detected before expensive collateral damage and unscheduled downtime occurs. The CMP enables daily inspections across numerous critical parameters. This capability delivers a huge benefit over less frequent oil sampling and other condition monitoring activities (vibe, thermography, acoustics, etc.).

Best applications include:

gearboxes,

bearing oil sumps,

hydraulic reservoirs,

compressor oil reservoirs,

turbine-generator

main oil tanks and

paper machine central reservoirs.

Comprehensive Inspection

Most sight glass level gauges are used only to confirm oil volume. Many root causes and symptoms of machine failure are missed due to the limited ability of these sight glasses. The CMP is a multi-parameter inspection pod that greatly modernizes and expands daily one-minute inspections.

The magnetic plug picks up any metal findings and wear debris.

Specifications

2.75” x 3.18” x 3.5” (w x h x l)

Large acrylic sight glass with 1.4” diameter x 1.25” deep viewing area

Aluminum Body

Zinc plated Steel Adapter with 1” male pipe threads. 3/4” and 1/2” adaptors coming soon.

Stainless steel Pilot Tube bent to your specifications

Magnetic plug made of a powerful neodymium rare earth magnet

M16x2 Sample Port threads for attaching to vacuum pump and sample bottle

Viton O-Ring

Part Numbers

| CMPOD.050NPT | 1/2" NPT | .17 fl.oz |

| CMPOD.075NPT | 3/4" NPT | .29 fl.oz |

| CMPOD.100NPT | 1" NPT | .58 fl.oz |

| CMPOD.125NPT | 1-1/4" NPT | .58 fl.oz |

| CMPOD.150NPT | 1-1/2" NPT | .58 fl.oz |

| CMPOD.050BSPP | 1/2" NPT | .17 fl.oz |

| CMPOD.075BSPP | 3/4" BSPP | .29 fl.oz |

| CMPOD.100BSPP | 1" BSPP | .58 fl.oz |