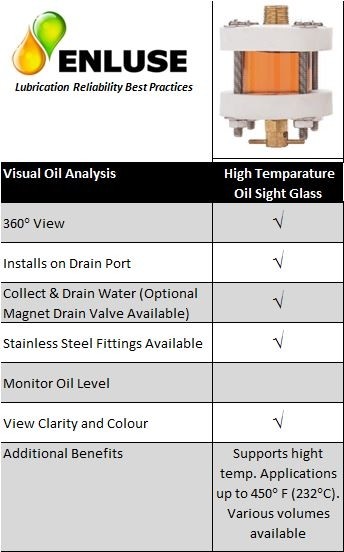

►Hex-Duty Oil Sight Glass (OSG)

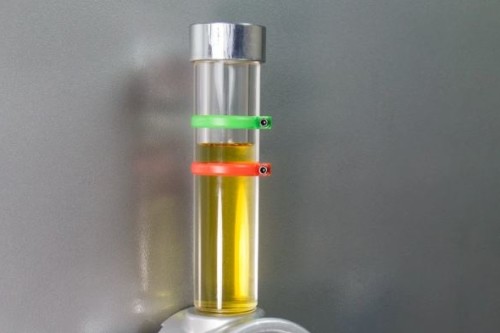

The Hex-Duty Sight Glass is stronger and more durable, with double the pressure rating at 400 psi. The new hexagonal design allows for easier installation, draining and disassembly. Available in 1-ounce and 3-ounce bottle sizes, with either a ¼”, 3/8”, ½” or ¾” NPT.

Water wreaks havoc on lubrication systems, causing premature wear. With the Hex-Duty OSG, you have immediate visual inspection of the oil and the ability to drain and accumulate water. The OSG is installed directly to a drain port located at the bottom of a reservoir or with an elbow for drain ports located on the sides of equipment. The spring-loaded drain valve is utilized to purge any accumulated water. Any sediment or particles in the lubrication fluid will matriculate to the OSG where, upon inspection, you can determine appropriate action. The OSG is perfect on

Material

- Cast acrylic

- Brass nipple

- Brass drain valve

Recommended Temperature Range

- -40° F to 200° F

- -40° C to 93° C

- Up to 400 psi

Available Options

- 1 oz and 3 oz bottle sizes

- 1 oz model has a ½” NPT installation port (adaptors available for other sizes)

- 3 oz model has a ¾” NPT installation port (adaptors available for other sizes)

- Stainless steel hardware

- Magnetic drain valve for ferrous particles

Applications

- pumps,

- gearboxes,

- storage tanks

- fluid-lubricated machinery