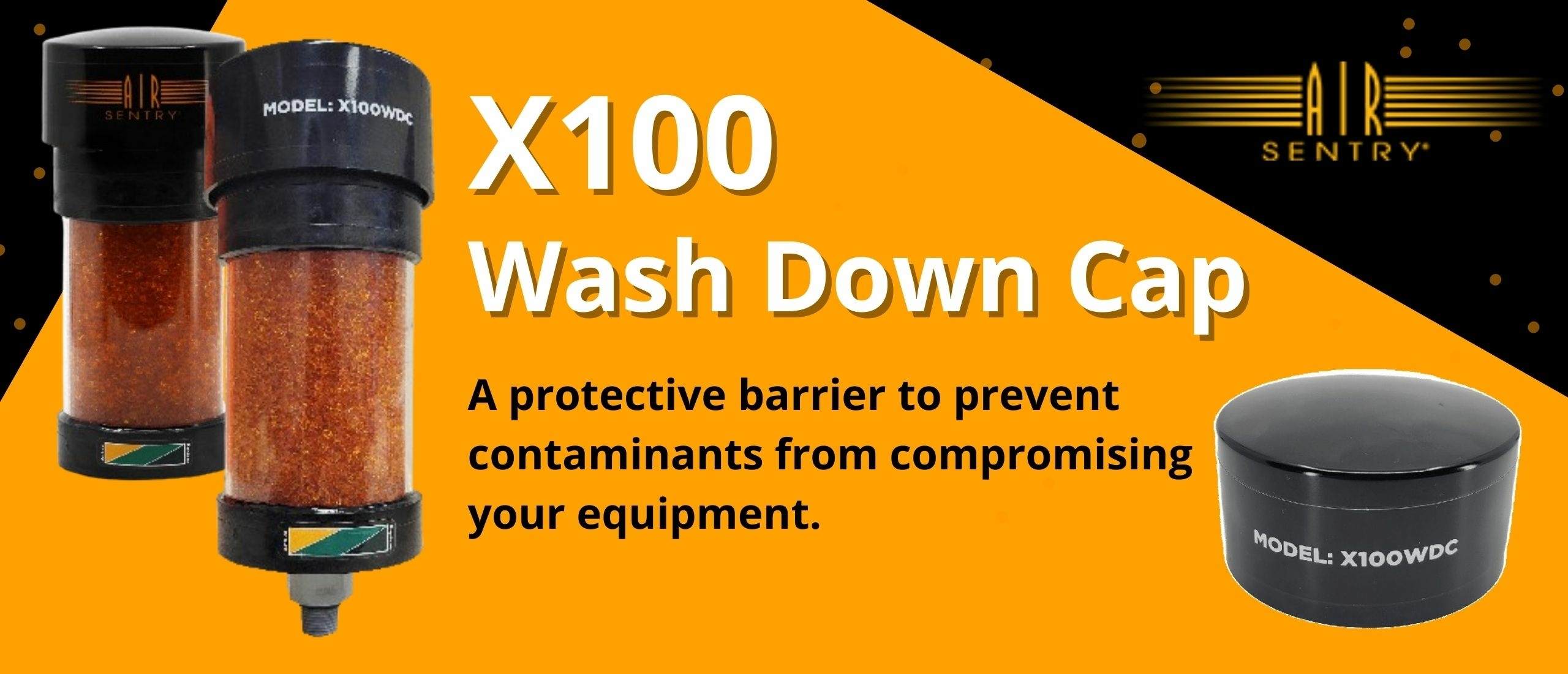

Maximize Protection - X100 Wash Down Cap with X100 Breather Compatibility

In industries where frequent equipment washdowns and dust pose significant challenges, maintaining contamination control becomes paramount. Enter the X100 Wash Down Cap, a robust protective barrier designed to withstand harsh environments and prevent contaminants from compromising your equipment.

X100 Wash Down Cap Overview

The X100 Wash Down Cap is a specialized solution crafted to excel in environments requiring regular equipment washdowns, such as those found in the food processing, mining, cement, and pulp and paper industries. Its primary function is to act as a shield against direct spray, effectively safeguarding check valves within the top cap.

Wash down cap X100 breather

Wash down cap X100 breather

Key Features

Frequency of Use: Tailored for environments with frequent equipment washdowns.

Dust Protection: Effectively prevents dust from compromising equipment functionality.

Industry Compatibility: Ideal for diverse industries, including food processing, mining, cement, and pulp and paper.

Compatibility with X100 Breather Model

The X100 Wash Down Cap seamlessly integrates with the X100 Breather Model, providing a comprehensive solution for contamination control. This compatibility ensures a cohesive and effective system that addresses the unique challenges posed by specific industries.

X100 Desiccant Breather with wash down cap

X100 Desiccant Breather with wash down cap

Specifications

Part Number: X100WDC

Compatibility: X100 Breather Model

Application: Designed for industries such as cement, construction, food and beverage, mining, and pulp and paper.

Common Uses and Industries

The X100 Wash Down Cap finds its application in a range of industries, offering tailored contamination control solutions.

Common uses include:

- Cement Industry: Protects equipment from dust and water exposure during the production process.

- Construction: Ideal for equipment used in outdoor construction sites subject to frequent washdowns.

- Food & Beverage: Ensures food processing equipment remains uncontaminated, meeting stringent industry standards.

- Mining: Shields mining equipment from both dust and water, extending operational life.

- Pulp & Paper: Vital for maintaining equipment integrity in paper manufacturing processes.

Conclusion

In the quest for effective contamination control, the X100 Wash Down Cap stands out as a reliable and versatile solution. Its compatibility with the X100 Breather Model, coupled with robust features, makes it a valuable asset for industries where equipment resilience is crucial. Whether in cement production, mining operations, or food processing, the X100 Wash Down Cap proves itself as a proactive measure against the challenges posed by frequent washdowns and dust exposure.