Constant-Level Oilers-Keeping Machines Running Smoothly

The proper lubrication of moving parts stands as a fundamental pillar of operational efficiency and longevity. Constant-Level Oilers, a relatively simple yet highly effective mechanism, play a crucial role in maintaining optimal lubrication levels in various types of machinery.

Constant-Level Oilers

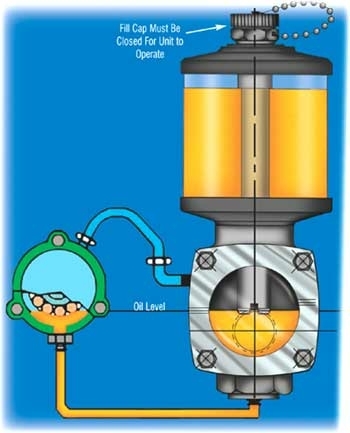

Constant-Level Oilers are devices designed to maintain a consistent level of lubricating oil within a piece of machinery or equipment. They operate on a straightforward principle: as the lubricant is consumed or displaced, these Oilers automatically replenish the supply to maintain a preset level.

By equalizing the pressure between the oiler and the equipment the level is more accurately maintained, creating a closed-loop system.

By equalizing the pressure between the oiler and the equipment the level is more accurately maintained, creating a closed-loop system.

The system typically consists of a reservoir, a float mechanism, and a valve assembly. The reservoir holds the lubricant, while the float mechanism adjusts with the changing oil levels. When the oil level drops, the float activates the valve, allowing more lubricant to enter the system until it reaches the predetermined level.

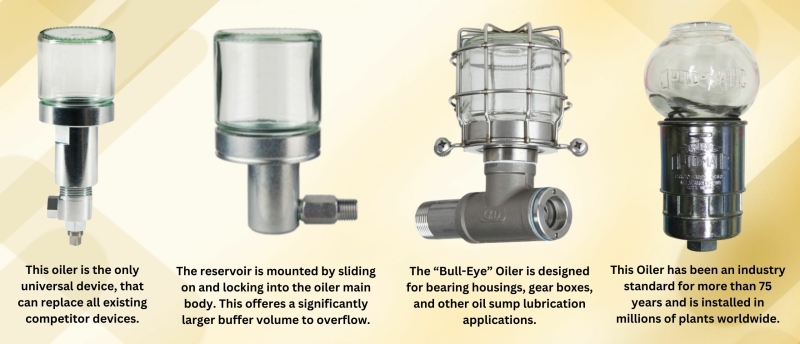

Discover Our Diverse Range of Constant-Level Oilers

Explore a snapshot of our extensive assortment of constant-level oilers. While not exhaustive, you can download our brochure below or contact us for more details. Experience our comprehensive offerings designed to maintain consistent lubrication in your machinery.

# RM-OWFOO - Bull Eye Constant-Level Oiler

The Bull Eye Constant-Level Oiler stands out with its distinctive features:

- Robust Construction: Designed to endure the harshest operational environments, ensuring unwavering reliability and longevity.

- Material Variants: Crafted from durable stainless steel 1.4404 (316L) or zinc-plated mild steel, guaranteeing structural integrity and resilience. No compromise on quality; solid steel is employed instead of zinc die-cast or other coloured metals.

- Enhanced Design: A two-piece construction eliminates the need for braising or welding, while covered venting (IP 44) offers resistance against spray water and dust. The wide opening (170°) facilitates easy filling, and the reservoir is replaceable, ensuring convenience and adaptability.

- Versatile Application: The Oiler, available with or without a wire guard, finds its niche wherever maintaining a consistent fluid level is paramount. Predominantly used for lubricating bearings, it also serves as a reservoir for quenching mechanical seals and various other applications. The combination of stainless steel with PTFE gaskets extends its usability even with aggressive fluids.

- Adaptability: Notably, the glass reservoir is interchangeable with a plastic one, allowing for versatility in application scenarios.

- Connection Variants: These exceptional oilers are available with multiple connection options, catering to diverse installation needs. From threaded connections to flange fittings, each variant ensures a secure and adaptable installation process. Whether it's NPT, BSP, BSPT or custom connections, the oiler offers a seamless fit into various systems, enabling hassle-free integration.

- Sealing Expertise: The seal is a critical component ensuring leak-proof functionality and fluid containment. The bull-eye constant-level oiler showcases a wide range of sealing materials, providing compatibility with different fluids and environments. With options such as PTFE, FKM or SBR seals, these oilers effectively prevent leaks and maintain a secure seal even with aggressive or corrosive fluids.

- Robust Design and Resilience: Beyond its diverse connection options and superior seals, the bull-eye constant-level oiler boasts a robust construction that endures demanding operational conditions. Crafted from stainless steel 1.4404 (316L) or zinc-plated mild steel, these oilers prioritize durability, ensuring extended service life and reliability even in the toughest environments.

- Adaptable Applications: The versatility of these constant level oilers extends beyond their connection and sealing capabilities. Designed with adaptability in mind, the bull-eye constant-level oiler seamlessly integrates into various industrial applications. Whether it's for lubricating bearings, quenching mechanical seals, or other critical uses, these oilers offer exceptional fluid level maintenance while accommodating different fluid types and conditions.

# RM-OWFWG - same as RM-OWFOO but with Stainless steel wire guard.

# RM-OWFPL - same as RM-OWFOO but with plastic ( PA6 ) reservoir.

Various Constant-Level Oilers

In essence, the Level Oilers embody precision, adaptability, and endurance, making them a reliable choice for diverse industrial applications. Whether for lubrication, sealing, or other fluid level requirements, these German-made oilers set the standard for performance and durability.

Importance in Industrial Applications

In various industrial applications, machinery operates under demanding conditions, subject to continuous motion, high temperatures, heavy loads, and challenging environments. Insufficient lubrication or inconsistent oil levels can lead to increased friction, overheating, accelerated wear and tear, and ultimately, equipment failure.

Constant-Level Oilers address these concerns by ensuring a steady supply of lubrication, which contributes to:

- Enhanced Equipment Longevity: Proper lubrication reduces friction, preventing premature wear on moving parts and extending the lifespan of machinery.

- Improved Operational Efficiency: Consistent oil levels enable machinery to operate smoothly, minimizing downtime due to maintenance and repairs.

- Cost Savings: By reducing the frequency of manual lubrication checks and decreasing the likelihood of machinery breakdowns, constant-level oilers can result in cost savings over time.

- Environmental Benefits: Accurate lubrication levels can reduce oil wastage and potential environmental contamination, promoting sustainability in industrial operations.

Applications Across Industries

Constant-Level Oilers find applications across diverse industries:

- Manufacturing: Used in conveyor systems, pumps, and other machinery in factories and production lines.

- Automotive: Applied in engines, transmissions, and other critical components to ensure proper lubrication.

- Marine: Employed in marine engines, propeller shafts, and auxiliary machinery on ships to maintain optimal oil levels.

- Power Generation: Utilized in turbines, generators, and rotating equipment to sustain efficient operation.

Factors Influencing Selection and Installation

Several factors influence the selection and installation of Constant-Level Oilers:

- Type of Machinery: Different machines require specific types and sizes of oilers to meet their lubrication needs.

- Operating Conditions: Considerations such as temperature variations, vibrations, and exposure to contaminants influence the choice of oiler materials and design.

- Lubricant Type: Compatibility with the lubricant used is essential to prevent degradation or malfunction of the oiler system.

- Maintenance Requirements: Understanding the maintenance needs of the constant-level oiler is crucial for sustained performance.

Conclusion

Constant-Level Oilers stand as indispensable components in the realm of machinery and equipment maintenance. Their ability to ensure consistent and adequate lubrication levels contributes significantly to the smooth operation, longevity, and cost-effectiveness of industrial equipment across various sectors.

As technology continues to evolve, advancements in materials, designs, and automation further enhance the efficiency and reliability of these oilers, promising even greater benefits for industries reliant on smoothly running machinery. Investing in and understanding the significance of constant-level oilers can undoubtedly pave the way for more efficient, sustainable, and reliable industrial operations.

For more information reach out to us

Link to the flipbook.

* Note:

Source: Machinery Lubrication: Constant-level Oilers by Carolyn Boldt