10. Feed the Brain and Train

When lubricant is the lifeblood of your equipment, good lubrication practice includes several elements. Nine of them have been discussed in the foregoing chapters. Today step 10 will be looked upon: Training and Education.

Around the world lubricant is added to machines every day. This to prevent failure and preserve the lubricant function, i.e. overcome friction. If friction is the enemy to reliability, an effective lubrication program is absolutely essential.

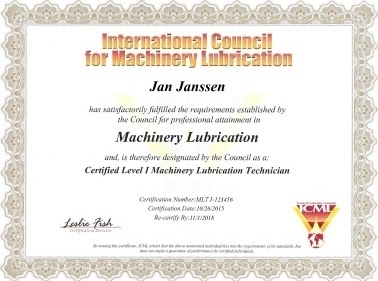

Educating the work force is a fundamental element of a good lubrication program. The people who lubricate the equipment need to be Machine Lubrication Technician (MLT*) trained and certified. The days when lubrication was performed by everyone and anyone are gone.

MACHINE LUBRICANT ANLYST (MLA)

Level I Machine Lubricant Analyst

The Machine Lubricant Analyst/Machinery Lubrication Technician Level I course is aimed at plant or shop technicians responsible for lubricating and maintaining machinery.

Your daily activities consist of oil sampling, contamination control, handling, receiving and storing lubricants, oil changes, and basic machine condition monitoring.

Level II Machine Lubricant Analyst

Level III Machine Lubricant Analyst

The International Council for Machinery Lubrication (ICML)

ICML is a global non-profit organisation dedicated to helping lubrication practitioners succeed in their professional careers. ICML certification exams are in accordance with ISO 18436 and are available worldwide, in multiple languages.

Make Your Lubrication Programme Visible!

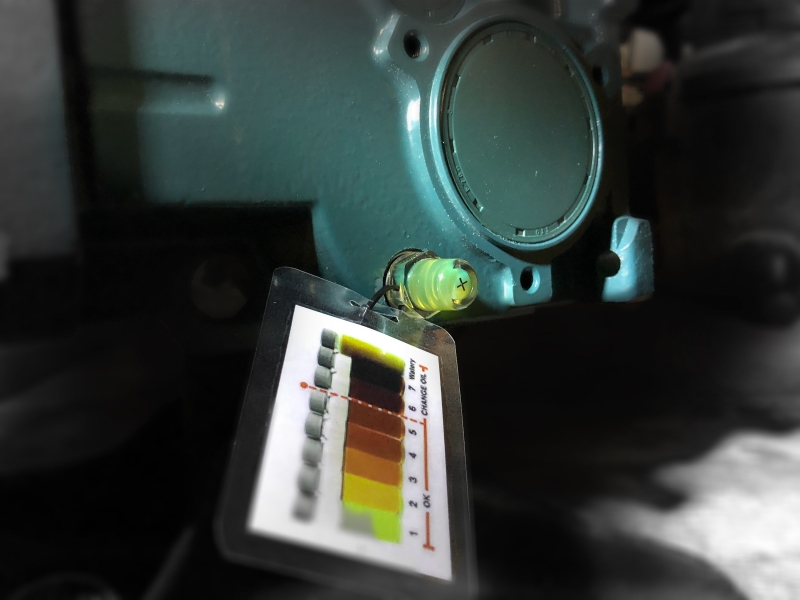

Even though the vast majority of your lubrication programme will not be completed by your MLTs and MLAs, your lubrication programme will typically need to become more visible. All lubrication points should be documented, put into lubrication routes, and labelled for the correct type and amount of lubricant.

Lubrication sight glasses should be clearly labelled with a green area showing the correct level, and red areas that clearly indicate too much or too little lubricant. Lubrication points can be colour coded to match the colour of the lubrication dispenser to help make clear that the correct type of lubricant is being added.

Operator Lubrication Tasks

Operator Care and Total Productive Maintenance (TPM) can be very powerful tools to help improve the reliability of your assets. The key here is to ensure that tasks are transferred at the correct level; operators should only be performing lubrication tasks on equipment they are responsible for operating and the tasks they perform should be required each day or each shift.

Those who start out with good intentions train people, transfer the tasks, and audit for a short time, but the next thing they know, three new operators who have never been trained in how to properly perform the task are running the equipment. In no time at all, there is a rash of lubrication-related equipment failures.

All who make this step be certain that you take the time to think through how you plan to manage the programme on a daily, weekly, monthly, quarterly, and annual basis. Make sure to include up front how you will manage changes in personnel in terms of operators, MLTs and MLAs.

Source:

MaintWorld-Lubrication Excellence