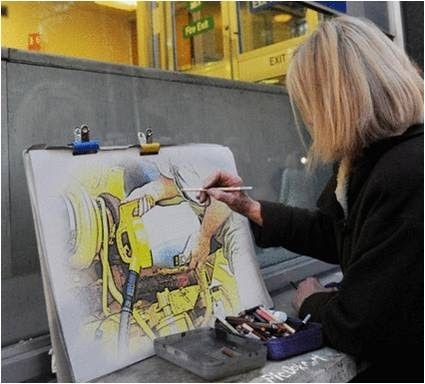

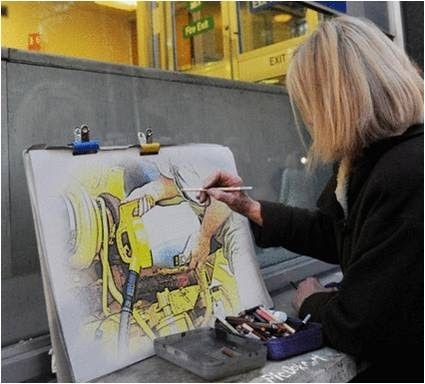

Is Oil Dispensing an Art....???

NO WAY!

It’s a question of using the right tools!

Have you ever left your lubricants, that you depend on to lubricate your machines, open to dirt and moisture?

Then no doubt you still use the old oil can with rags. The reason that your expensive lubricants run the risk to get contaminated by dirt, water and other particulates. And even worse… your equipment get contaminated too. Since the smallest particulates can cause asset components to fail prematurely.

Another problem with oil transfer and oil storage methods is incorrect lubricant usage or lubricant cross contamination.

Fully sealing units are the solution to prevent contaminants from getting into the oil. Sealable, reusable oil storage containers are easy to dispense without the need for tools like funnels.

Another recommendation is integrating a colour-coded system, which includes properly labeled containers to prevent cross contamination, so that contents are easily identifiable.

For more information on the OilSafe assortment please download the catalogue.

Enluse can help you by supplying Best Practice lubricant storage and transfer container configurations. There are five lid types and five plastic oil storage body types to choose from. Lids are available in 10 colours so that you may maximise the visual identification aspect of this storage, transfer and handling tool.

Keep your business running with OilSafe!

In our series of "10 steps to Lubrication Reliability" we are now halfway.

Maybe you think: "This is a mission impossible".

In one GO.... Yes it is!