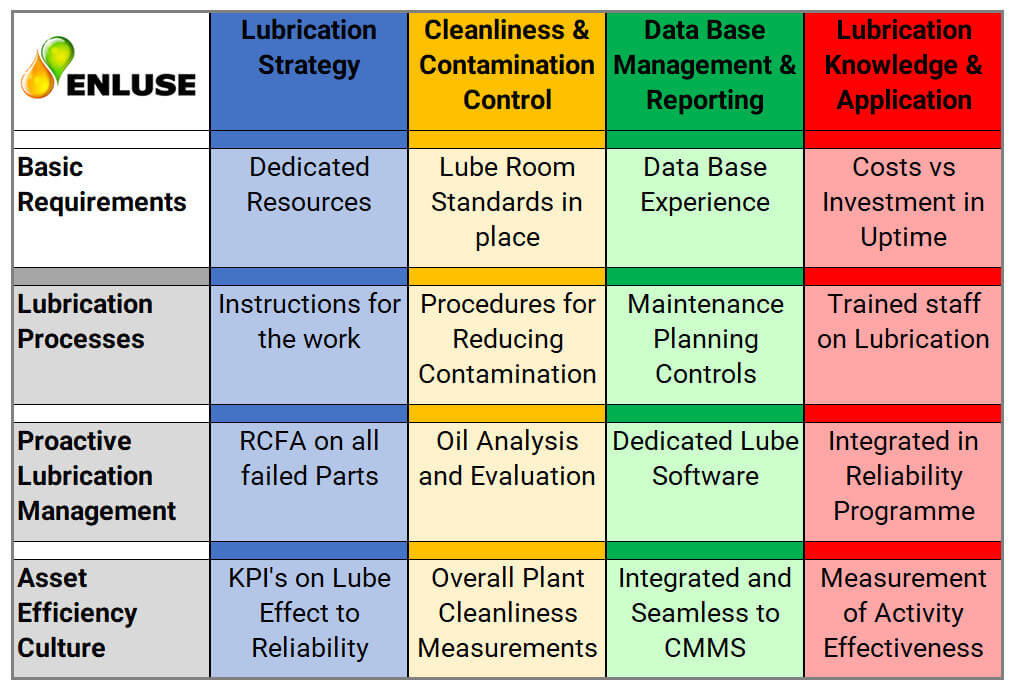

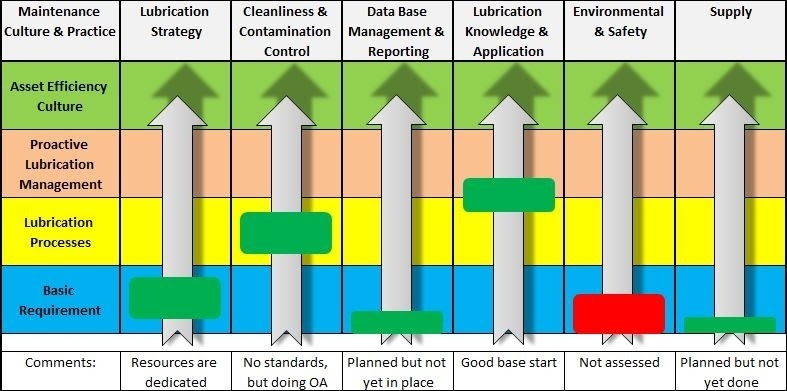

To start a new Lubrication Reliability (LR) strategy (or just implement one or more of its components) it is crucial to assess the actual lubrication management situation. Evaluation and benchmarking will disclose actual flaws in the organisation and stress out the weak points in the fields of:

- Strategies,

- CMMS,

- Cleanliness & contamination control,

- Lube supply,

- Expertise, etc.

Actual status is categorised from Basic Level evolving to Best in Class.