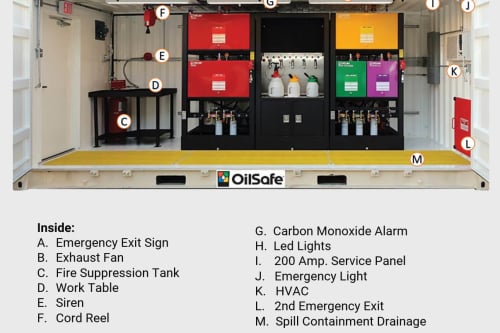

The Lubristation™ family of solutions for storage, conditioning and distribution/dispensing of lubricants are custom made systems. Assembled with modular components. Always having customer needs and requirements in mind, i.e.:

- place of use (compact or extended, fixed or mobile)

- number and type of lubricants (oil viscosity)

- consumption or packaging (bulk, 200 litre drums, small packaging, cans)

- budget (from basic to Best Practice with all options)

The ultimate purpose with Lubristation™ is to protect lubricants from contamination, increase cleanliness level and keep lubricants in optimal condition while lubricators finally can be proud of their equipment.