What is Wear?

What is WEAR?

Just looking at it from a DIN perspective, Wear is the continuing loss of material from the surface of a solid body due to mechanical action, i.e. contact and relative movement of a solid, fluid or gaseous counter body. The material removed by the wear process is designated as fines This is the fundamental.

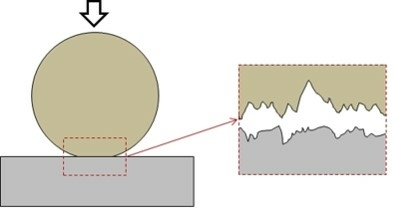

If you take this little graphic of the ball sitting on a solid plate with a lubrication film, they're never touching. They're separated by the lubrication film. And this is what lubrication is all about. If you don't have that separation, you have metal to metal touching, and you have wear.

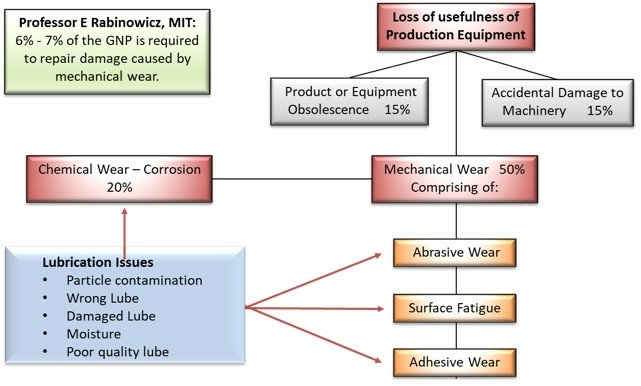

Another way to look at it is from Professor Rabinowicz. He's a professor at the Massachusetts Institute of Technology.

A few years ago he said that six to seven percent of the Gross National Product is required to repair damage caused by mechanical wear. What does he mean by that? He means: the cost of maintenance, the loss of usefulness of production equipment.

There are three sections he highlighted, generating 80 percent of that:

- Product or equipment obsolescence, which simply gets old and has to be replaced (15%).

- Damage caused to the equipment through any form of operation (15%).

But the biggest component of that is 50%, which is - Mechanical wear

Mechanical wear can also be chemical wear, corrosion.

But if you look at mechanical wear, there are three types of mechanical wear:

- Abrasive wear, where surfaces are rubbing together

- Surface fatigue, where the surfaces get damaged and fatigued

- Adhesive wear. Adhesive wear is the result of the transference of material from one surface to another, typically taking place in poorly lubricated sliding applications.

But if you take all of those three components and you take the chemical wear, they're all predominantly related to lubrication issues. You have:

- Particle contamination, too many particles or dirt in the oil.

- Maybe you've got the wrong lube.

- Maybe the lube is damaged because you've mixed the lube. It losts its chemical properties.

- You've got water in it or

- It's just poor quality lube.

When focusing on these lubrication issues, we will support the elimination of wear. As we can see from what the professor is saying, if we can do this, we not only save a lot of money for the company, but we save a lot of money for industry alone.