How to load a Grease Gun

Service Instructions for Grease Guns

The grease gun is one of the most widely-used tools for machinery lubrication. However, loading a grease gun is for many people not a regular task. Exception is of course when working with machines that need greasing every day.

In this blog the multiple loading options of a grease gun are described. How to load a manual grease gun using f.i. a cartridge, then priming it and finally getting air out of a grease gun prior to use. Be aware, that you should always consult the manuals and manufactures instructions to make sure you are following the correct way to use a grease gun under their specifications and instructions, as failing to do this might result in damages and possibly injuries.

When one doesn't know how to load a grease gun, it can become a safety risk to both the lubrication technician and the machine.

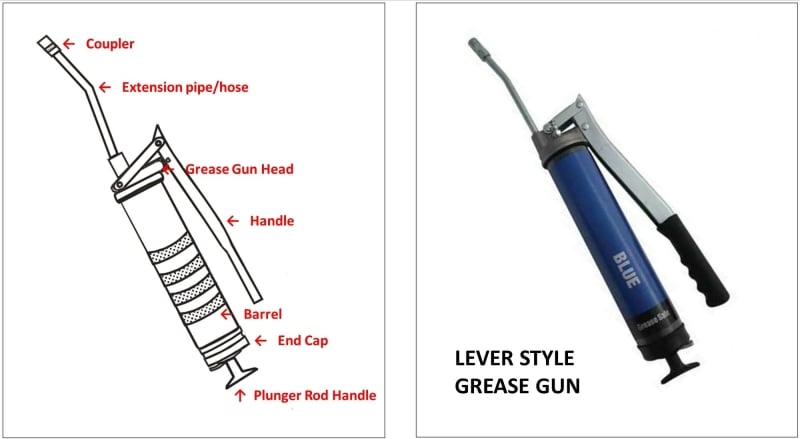

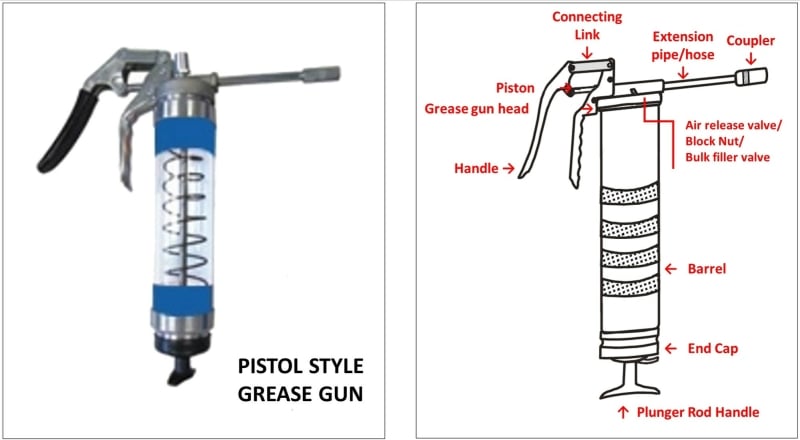

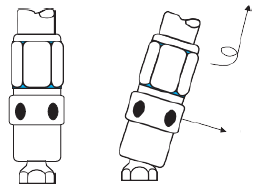

Nomenclature Grease Gun

Grease Gun Loading

- Cartridge loading: paper or plastic cartridge

- Bulk loading

- Suction loading

- Filler pump loading (only on grease gun models with bulk loader valve)

! CAUTION

Grease or an empty cartridge in barrel is under pressure from the internal spring, use caution when removing either end of the barrel.

Follow the steps below for the appropriate loading option:

| Cartridge Loading | Bulk Loading | Suction Loading | Filler Pump Loading | |

| 1 | Unscrew Grease Gun Head from the Barrel counter-clockwise. | |||

| 2 | Pull back the Plunger Rod Handle all the way back and lock it with the End Cap. | Insert the open end of the Barrel into the Grease bucket to about 2" (50 mm) deep. | Pull back the Plunger Rod Handle all the way back and lock it with the End Cap. Screw back the Grease Gun Head tightly into the Barrel. | |

| 3 | Remove the plastic cap from the open end of the Grease Cartridge and fully insert into the empty Grease Gun Barrel. Make sure the rim of the Cartridge is seated on the rim of the Barrel. | Scoop out clean Grease from the Bulk Grease Container into the empty Grease Gun Barrel. | Now, slowly pull back the Plunger Rod Handle all the way back, to draw in grease into the empty Barrel. Lock the Plunger Rod with the End Cap. | Ceck compatibility of Bulk Filler Valve on your grease gun with your Filler Pump, to make sure they are compatible. Wipe the Bulk Filler Nipple clean of any dirt before starting. |

| 4 | Remove the metal Pull tab seal from the Grease Cartridge. | Once the Barrel is full, shake the Barrel to allow grease to settle down. Fill in more grease if additional space is created in the Barrel, to completely fill it. | Shake the Grease Gun Barrel to allow the Grease to settle down. | Insert the Bulk Filler Valve into the Female Loader Valve of the Grease Filler pump. Start operatingthe Filler Pump, keeping your hand on the Grease Gun, lightly pushing it down onto the Filler Pump. Once the Grease Gun Barrel is filled, pumping would get very hard. Stop at this time. |

| The plunger assembly is capable of cartridge, bulk, suction, and filler pump loading in the "as-is" condition. There is no need to manipulate the plunger assembly based on fill type. | ||||

| 5 | Screw back the Grease gun Head onto the Barrel, making sure to tighten only half-way, leaving 2-3 turns before the Head is fully tight. | Disengage the Gear Filler Valve from the Female Loader Valve of Grease Filler Pump. Unscrew Grease Gun Head from the Barrel by a few turns, such that it is about 2-3 turns loose. | ||

| 6 | Disconnect the Plunger Rod from the End Cap. | |||

| 7 | Force the Plunger Rod in and out a few times in order to compress the grease and force out trapped air in the grease to come out from the loose connection between the Grease Gun Barrel and the Grease Gun Head. | |||

| 8 | Hand tighten the Grease Gun Head fully onto the Barrel. | |||

| 9 | Start operating the Grease Gun Handle till grease starts flowing out continuously. (Note that the first discharge of grease may have some air bubbles). If grease is accompanied with air bubbles, repeat steps 5, 6, 7. 8 to prime** the Grease Gun. | |||

| 10 | Once all air bubbles are removed, fully tighten the Grease Gun Head onto the Barrel. (Note that when the Grease Gun is in continuous use, pressing the Air Release Valve* helps force out trapped air). Now, connect Grease Gun extension and Coupler onto the Grease Gun Outlet using a thread sealant such as Teflon, to make a seal-proof connection. (DO NOT over tighten as this may fracture the Grease Gun Outlet). |  Air Release Valve | ||

| 11 | Start operating the Grease Gun. Grease will begin to flow out from the coupler. Keep running it, till a bubble free clear stream of grease flows out. If this does not happen, then there is still some trapped air in the grease. Repeat the steps 5, 6, 7 and 8 to Prime* the Grease Gun. | |||

* On Grease Gun models fitted with Air Release Valve

** Priming Grease Guns

A common occurence with all grease equipment is trapped air pockets in grease. Trapped air causes zero or reduced grease discharge. Removing Air Pockets from Grease is referred to as Priming or Air Bleeding.

It is highly recommended to prime the Grease Gun, before it's used for the first time. Also, anytime in operation, if grease stops coming out, the most probable cause is trapped air in grease. Refer to steps 5-9 for Priming of Grease gun.

If the Grease gun has been in regular use, Priming can be done without having to remove the Grease Gun Extension and Coupler from the Grease Gun Head.

Greasing a Grease Fitting / Grease Nipple

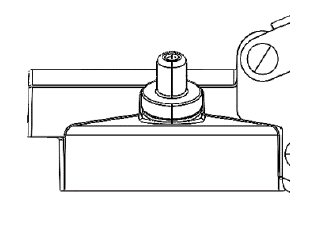

The grease coupler provided at the end of the grease gun extension has a jaw type construction. The coupler jaws will snap on to a grease fitting and maintain a tight fit.

When connecting the coupler to the grease fitting, press the coupler straight onto the grease fitting to form a snug fit. Start operating the grease gun with the coupler as square to the grease fitting as possible.

Once greasing is completed, slightly tilt the coupler, twist and pull back. The tilt and twist action will allow easy removal of the coupler from the grease fitting.

It is important to maintain a clean work environment when greasing equipment:

- Prior to injecting grease, wipe grease fittings clean to prevent contaminant ingestion.

- After greasing, wipe the fitting too.

- To keep the gun nozzle clean during storage, wipe excess grease off the nozzle and cover it with a cap.

! Warning To remove, Tilt, Twist and Pull

To remove, Tilt, Twist and Pull

Never try to dis-engage the coupler by pulling it out straight

Trouble Shooting

| Problem | Cause | Remedy | ||

| 1 | Grease Gun pumps little or no grease | a) Trapped air pockets in grease | a) | Prime grease gun |

| b) Thick grease or frozen grease | b) | Use a lower viscosity Grease / add some oil to grease to make it more viscous / Heat the Grease Gun Barrel to unfreeze the grease | ||

| c) Blocked grease gun extension | c) | Remove Grease Gun Extension. If Grease gun pumps grease without the extension, then the probem is with the extension, which should be cleaned/replaced. | ||

| d) Blocked grease gun head | d) | Dis-assemble the Grease Gun Head to check for any contaminants blocking the passage of grease. Clean and re-assemble the Grease Gun Head. | ||

| 2 | Excessive Grease Leaks out from the back side of the Grease Gun - around the Plunger Rod. | a) Damaged Grease Gun Rubber Follower. | a) | Changer Follower. |

| 3 | Grease leaks from the connection between the Grease Gun Head and the Extension / Extension and Coupler. | a) Loose Connection. | a) | Tighten the connection using Teflon or any other Thread Sealant. |

| 4 | Grease leaks from the Coupler body joint or from in-between the Coupler Jaws and Grease Nipple. | a) Damaged Grease Coupler. | a) | Change Coupler. |