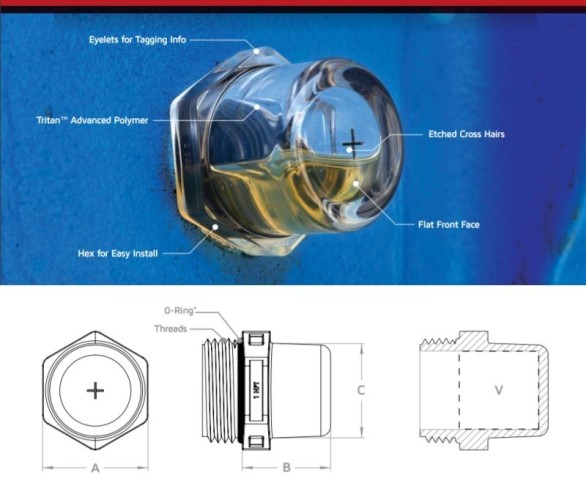

►3D Oil Sight Glass (BullsEye)

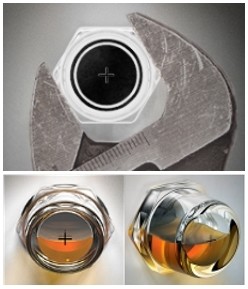

The 3D Oil Sight Glass (BullsEye) can be looked upon as a small window into our machine, providing a wealth of information. Apart from indicating that there is enough oil in the sump, the 3D oil sight glasses also offer an opportunity to monitor the oil. It's a first-hand account of any problems that are occurring.

The BullsEye 3D Oil Sight Glass is threaded into a port, where the oil level should be maintained during operation (oil level is half way up the sight glass).

Advantages of a 3D Oil Sight Glass:

oil level confirmation

aerated oil detection

foam detection

water emulsion detection

oil volume detection

oil colour detection

easy to install

Whatever level is seen in the BullsEye is what the oil level actually is.

Installation

Installing a sight glass is a relatively simple process. However, if the sight glass is not properly installed, the oil readings will be wrong, which means trouble!

Example of how to install a Luneta oil sight glass:

- Apply thread sealer to the threads before installation.

- Hand-thread the Sight Glass into the port.

- Use a crescent wrench or 1-5/16" socket wrench to tighten until the hex nut contacts the port face (or if applicable, until the O-ring is compressed).

- Check for leaks and apply more thread sealer if necessary.

- Do not over-tighten.

Applications

- Storage Tanks

- Pumps

- Viewport Replacement

- Gearboxes

Available Thread Options

- NPT

- Metric

- BSPP