Once lubricants are applied to the machine, the same strategy should be implemented:

7. Contamination Control

AVOID FURTHER CONTAMINATION

and if possible

DECREASE EXISTING CONTAMINANT LEVELS

Typical Contaminants

While oil contamination takes many forms, the following three classifications cover the majority of industrial problems:

- Dirt - Dust and solid contaminants creep in from the surrounding atmosphere. Contaminants could include metal chips from machining, rust and wear products from seals, bearings and gears, core sand from castings, weld spatter from welding, paint flakes from painted surfaces and soot from diesel engines.

- Water - The most troublesome sources are often condensation, cooler leaks, gland leakage and seal leakage.

- Sludge - This forms primarily as a result of oxidation of the oil itself, especially at high temperatures. Accumulation of fine particles may also fill clearance spaces by silting, resulting in erratic operation and sticking of hydraulic system valves and variable flow pumps.

Different filtration specifications are required for each of these contaminants. With particulates, the maximum particle size should be kept below the minimum thickness of the fluid film.

With water, any free moisture may promote both rust and sludge by reacting with oil additives and metal surfaces. The critical limit of free water in the lubricant is the amount that causes the fluid film to fail in the load zone.

Once sufficient oil storage has been established, the next place for oil particulate contamination to occur is once the oil is in the machine or component.

This can happen in many ways:

- Open vents provide an easy means for dirt to enter machines.

- Faulty breathers are a common source of particulate contamination.

- Oil leaks or damaged seals are also culprits.

Remember, if oil is able to leak out of a system, contaminants are able to enter the system. Repair damaged seals or oil leaks as soon as possible!

Internal Contamination

Some form of internal particulate contamination is inevitable and can denote a problem with the machine/component. Internal particulate contamination includes any particles that contaminate the oil once it has been placed in the closed lubricated system - for example, wear particles, seal material etc. When external particulate contamination is under control, a high particle count provides an early warning for an abnormal wear situation developing.

Particles, especially catalytic metal particles like copper, iron and lead, increase the oxidation rate. These particles also strip the oil of its anti wear additives, extreme pressure additives, rust inhibitors and dispersants. Numerous small particles in stable suspension can cause the oil's viscosity to increase and may promote foaming.

These particles are abrasive. As with all particulate contaminants, once in the oil, they accelerate the wear rate dramatically because abrasive wear can cause a chain reaction in lubricated machinery. The typical chain reaction is:

- Abrasive wear particles become work hardened.

- Work hardened particles produce more particles.

- New particles become work hardened.

- Chain reaction occurs until the particles are removed by filtration or the machine fails.

It is, therefore, imperative to monitor oil cleanliness and keep particulate contamination to a minimum. This is accomplished by implementing a contamination control program in these easy steps:

Contamination Prevention

After ensuring oil is free from contamination, consider the times when servicing the machine becomes necessary. When component changes or work is performed on the machine, make sure that all new components are free from contamination and that further contamination does not enter the machine during servicing.

Ensure that all seals and breathers remain intact to prevent contaminant entry.

Contamination Removal

Contamination removal is accomplished with filters and filtration systems or oil draining and discarding. Each application must be evaluated when deciding which option is more cost-effective. Using filters to achieve target cleanliness levels does not always require the best or most expensive filter. A cheaper filter used correctly may produce the desired results at a lower cost. The effectiveness of a filter or filtration system can be tested by taking representative oil samples from before and after the filter. Controlling the contamination of oil inside the equipment is critical.

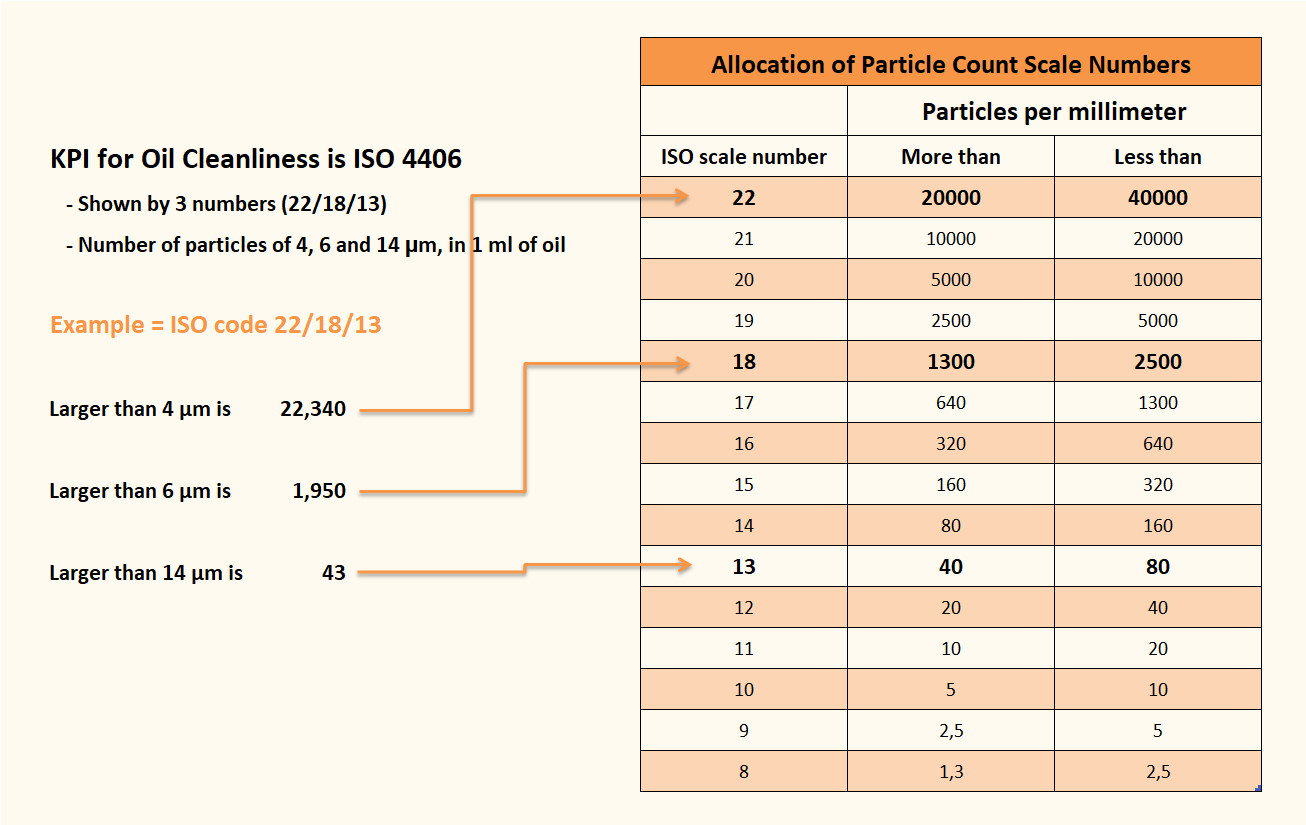

The international standard for measuring this is ISO 4406. Online and offline filtering systems are used to clean up the oil, while breathers or air conditioners are utilized to protect the lubricant.

ISO 4406 code

The ISO cleanliness code is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes 4 µ ©, 6 µ ©, and 14 µ ©. The ISO code is expressed in 3 numbers (i.e. 19/17/14). Each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. It is important to note that each time a code increases the quantity range of particles is doubling.

Monitoring Cleanliness Levels

For effective monitoring of the oil, check for cleanliness levels in the machine as well as at several other points, such as new oil sources, bulk tanks or stored lubricants, or oil in service in equipment.

To monitor the level of contamination, test the oil and obtain a particle count.

Oil analysis is uniquely suited for proactive measurements such as the testing of incoming lubricants, contamination control, measuring water and dust in oil, and determining when oil is deteriorated or unfit for use.